CFS 30 SL Elba concrete batching plant for research

Resource-saving, sustainable carbon concretes are being developed and tested at the HTWK in Leipzig. The modern building material is mixed in an Ammann CFS 30 SL Elba concrete mixing plant as part of the application-oriented research project – to deliver reproducible results.

Carbon concretes are the building materials of the future. In contrast to steel-reinforced concretes, concrete materials reinforced with carbon fibres are lighter, conserve resources, consume less energy and cause lower greenhouse gas emissions.

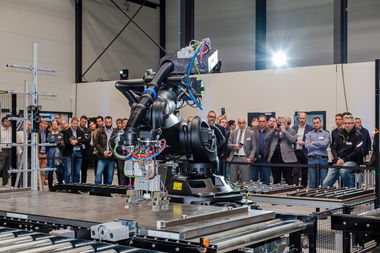

The HTWK Leipzig is playing a leading role in research into carbon concretes within the C3-Consortium (carbon concrete composite project). New concrete matrices, new building structures/construction methods using carbon concrete, new production processes and evaluation options for ecology and economy have been developed. With this background, the HTWK Leipzig participated in the construction of Germany‘s „Carbon Concrete Technology Center“. Inside this model factory, possibilities for production and evaluation are tested over an area encompassing 1000 m2, in order to bring the sustainable building material to market maturity faster.

In this globally unique research centre, according to the supplier, researchers rely on a compact concrete mixing plant from Ammann‘s CFS SL Elba series, which was developed for use in the recycling, landscaping, concrete goods and precast concrete sectors.

We needed a mixing plant that could reliably and reproducibly deliver the required mixing properties and functionalities, while the plant also had to be compact, efficient, and nonetheless flexibly adaptable,“ explains Dipl.-Ing. Otto Grauer, research assistant at the Faculty of Civil Engineering of the Institute of Concrete Construction, member of the Sustainable Building Research Group.

Small footprint, yet big space designed for flexible use

„An internet search and the positive experience of using the CEM 500 S solo mixer at the university led us to Ammann Elba,“ says Otto Grauer. Ultimately, the solution-orientated advice from the Ammann Elba customer advisers brought about the decision. „We were able to realise the plant features required for the project,“ says the engineer, describing the selection process.

The choice fell on the CFS 30 SL Elba concrete mixing plant from Ammann. The plant is equipped with an Ammann Elba CEM 500 S compulsory mixer (0.5 m³) with an hourly output of 30 m3. Thanks to its resolutely compact design – developed by Ammann engineers – it requires little space, yet is readily accessible for maintenance and servicing. The integrated pocket store enables the storage and weighing of 2.5 m3 of four aggregate types respectively. A 300 kg cement weigher with two cement screw connections and a water flow meter for precise water dosing ensure consistent, homogeneous, and rapid concrete production. An additive dosing system for the production of concretes with special properties has also been integrated. The fully automatic S-Mix control system facilitates freely preselectable recipes and product quantities.

Specially equipped for monitoring

In addition to the Ammann Elba mixing plant‘s high-quality standard equipment, the engineers required further options for the research project. As such, all aggregate components are equipped with a sand moisture measuring device, which allows documentation of the concrete production results in a reproducible manner. A special microwave probe, installed directly in the Ammann Elba CEM 500 S single-shaft compulsory mixer, is used to document the consistency during the mixing process. Thanks to the specially adapted mixer specifications, the researchers are able to reliably realise the special concrete properties required for carbon concrete in high quality.

„We are very satisfied with our decision,“ says Otto Grauer. „However, it turned out during operation that we required further additional functions, something that was no problem for the Ammann Elba engineers.“ Thanks to their good advice, swift delivery and the online service provided by the Ammann Elba customer advisers, the adaptations were implemented quickly and easily.

CONTACT

Ammann Elba Beton GmbH

Pforzheimer Str. 128b

76275 Ettlingen/Germany

+49 7243 720