Textile reinforcement for the new Bosphorus bridge

The worldwide tallest pylons of the giant building structure of the Bosphorus bridge in Istanbul rise up to an enormous height of 320 m. Curtain walls with reinforcement of Sodilian, the Albstadt-based specialist in textile reinforcement, were used for the construction of the pylons; the façade panels were realized for the Turkish company Fibrobeton. For the project team of Solidian just nine month remained from the first enquiry to the inauguration of the bridge last August, to realize the first structural analysis up to the installation of the façade with a surface of 3,200 m². In due time for the scheduled inauguration in the summer of 2016, the third Bosphorus bridge linking Asia and Europe was opened to traffic.

Supporting huge, innovative building projects by an in-house technical office was part of the philosophy and the range of services of Solidian, the specialist in reinforcement, right from the beginning, and this is highly appreciated by the customers using carbon and AR glass reinforcement. The Turkish giant project, which comes up with more than just one superlatives in terms of architecture and construction, turned out to be predestinated for using textile-reinforced concrete because the technical realization of the façade design of the pylons would not have been possible without the innovative material.

30 mm thin façade panels

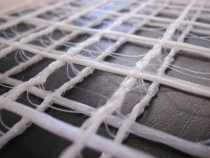

Apart from the height and the weight of the particularly spanning structure of the combined suspension and cable-stayed bridge, the high wind loads of up to 300 kg/m² above all turned the structure into a challenge not only in terms of statics but also for the assembly team. A maximum panel weight of 110 kg/m² was required for the façade panels used to protect the building structure because of the substructure and for handling purposes at high altitudes; this would not have been obtained by using conventional reinforced concrete. At first, the engineers of Solidian calculated the structural analysis according to specifications and developed an optimum geometry of the panels, which got a maximum dimension of 3.0 x 4.5 m, with being only 30 mm thin. Eventually, the required parameters could be achieved by using an ideal hybrid reinforcement of glass and carbon fiber meshes.

While Solidian immediately after the contract award in February 2015 started with the production, practical tests on the product during manufacturing confirmed the parameters previously calculated in the planning stage, thus providing for reliability already in advance.

Solidian also attended the production of the panels using Solidian GRID at the Turkish precast factory of Fibrobeton, where they provided support and advice on site, ensuring that assembly took place on schedule. The corrosion-free product solution meets the required 100-year durability and strongly confirms the potential of textile-reinforced concrete as a material of the future.