Textile-reinforced concrete produced with renewable raw materials

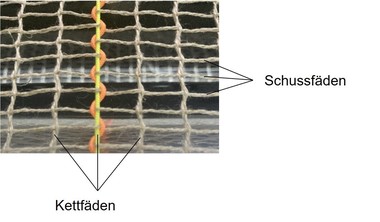

Adding steel to the concrete matrix is a long-established method that is at the same time necessary because concrete exhibits a high level of compressive strength but only limited tensile strength, which is why it always requires a supplementary material absorbing excessive tensile forces. The embedded steel needs to be covered with additional material in order to protect it from corrosive fluids. Hybrid structures built with textile-reinforced concrete address this issue and can open up new fields of application. One of these approaches practiced for the last couple of years is to substitute the steel by a textile reinforcement consisting of glass, carbon and/or plastic fibers, which provide the benefit of a non-existent or significantly reduced fiber corrodibility while reaching identical or higher tensile strength levels compared to steel. Furthermore, the same structural capacity can be achieved with reduced reinforcement cross-sections and a minimized nominal concrete cover, thus saving a significant amount of concrete. On the negative side, it should be noted that currently used fibers mostly consist of mineral-oil-based raw materials and that their production consumes a large amount of energy. Such synthetic fibers should also be viewed critically with regard to health and safety and the fact that there is currently no end-of-life disposal process. Certain natural fibers potentially provide alternatives to synthetic fibers. Bamboo, sisal, flax and hemp fibers, for example, also achieve very high tensile strength values. The properties of natural fibers are similar to those of glass fibers, but they are more ductile and basically carbon-neutral.