Reduction of CO2 emissions by means of calcined clays

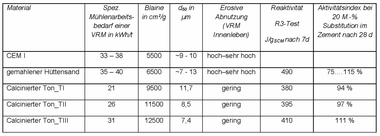

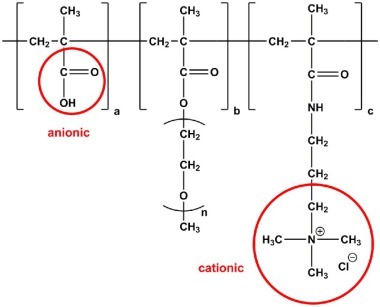

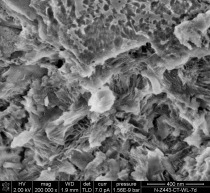

Calcined clays offer the opportunity to fulfil environmental requirements, to counteract the shortage of resources and to provide the market with high-performance binders, in synergy with other composite materials. Clays, which are of future interest, hardly release any carbon dioxide during the thermal activation (calcination) due to their chemo-mineralogical composition. Investigations on the availability of clay deposits [1] reveal a sufficient number of quarries in Germany. A selective calcination process in technical facilities is urgently required for a pozzolanic contribution of the clays, especially of their phyllosilicates, in concrete. Their properties, which significantly differ from those of glassy materials, require fundamental knowledge regarding workability and durability issues. It is commonly known that workability of fresh concrete is reduced with the addition of calcined clays due to their high specific surface area and an increased water demand. Heterogeneous surfaces, as can be found in clays with varying compositions, face concrete technologists with a huge challenge when selecting an appropriate superplasticizer. The lecture will provide possible approaches to this problem. Apart from ecological and economic requirements, the focus is legitimately also on the criteria of the durability of concrete in case of intended high substitution levels. Having the pozzolanic activity of calcined clays and the associated binding of calcium hydroxide in mind, the carbonization tendency requires extra attention. Investigations on different cements complying with DIN EN 197-1 with the addition of up to 25 wt. % of calcined clay reveal increased carbonization depths depending on the storage and phyllosilicates in calcined clay. However, they still meet the criteria for an adequate reinforcement protection. Therefore, calcined clays have the potential to become an important constituent for ecologically and technically optimized concretes.