New macro polymer fibers for load-bearing applications in concrete and sprayed concrete

With SikaFiber Force 50 and 60, Sika Deutschland GmbH launches two multitalented products as innovative concrete reinforcement. The high-performance polymer fibers produced in Germany are characterized by their particular surface structure ensuring a perfect bond to the concrete matrix. SikaFiber Force is also delivered in 400 kgs big bags so as to enable the use of automated dosing systems.

Due to stringent safety rules, extraordinary architecture and multiple functionality, the modern building material concrete is faced with enormous challenges. Polymer fibers of Sika provide concrete with more solid structures and stability. The newly developed SikaFiber Force macro polymer fibers improve the load-bearing capacity of concrete, increase its post-cracking tensile strength and reinforce concrete up to the surface. Both products are certified in accordance with DIN EN 14889-2, class II, and the structural effectiveness has been confirmed by the DIBt national technical approval Z-3.73.2149.

SikaFiber Force 50

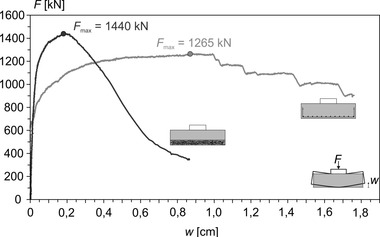

The structurally effective micro fiber for precast concrete elements and fair-faced concrete: SikaFiber Force 50 allows for the reduction of steel reinforcement or even its elimination. Moreover, the load-bearing capacity is increased and the abrasion resistance is improved. The product is used, for example, for ground slabs, precast concrete elements, foundations and footings as well as in traffic route construction. As the risk of corrosion does no longer exist, exposure classes XC (corrosion of reinforcement induced by carbonation) and XD (corrosion of reinforcement induced by chloride) are not applicable as well as the associated concrete cover. As a result, thinner structural components are possible.

Due to the elimination of steel reinforcement, concrete floors can be accessed by truck mixers directly, so that a concrete pump is no longer needed. The macro fiber improves the fatigue behavior of dynamically loaded traffic areas, thus extending their service life.

SikaFiber Force 60

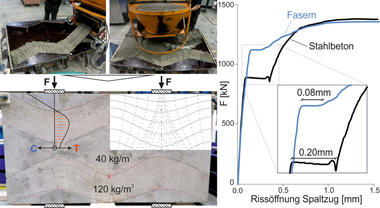

The optimized macro fiber for sprayed concrete: SikaFiber Force 60 was especially conceived for load-bearing applications using sprayed concrete. The main fields of application, for example, are sprayed concrete used as excavation protection in tunnel construction or as rock and soil stabilization. In case of sprayed concrete, with SikaFiber Force 60 the reinforcement is directly integrated in the spraying process. This reduces the effort required in comparison to conventional steel reinforcement because laborious and potentially dangerous installation of reinforcing steel mesh at uneven terrain is no longer necessary. The addition of SikaFiber Force 60 also improves the properties of hardened concrete: stainless surfaces, an increased energy absorption and an optimization of the post-cracking tensile strength, in particular, as far as large crack openings are concerned.

SikaFiber Force provides added value

Both SikaFiber Force 50 and Force 60 reinforce concrete up to the surface. In particular, as far as precast concrete elements are concerned, this ensures a significantly higher resistance to impact and shock loads, more stable edges and avoids transport and installation damages. As no reinforcement has to be installed, thinner components can be produced; a risk of corrosion does not exist and it is not necessary to keep stock.

The fibers made of polypropylene are packed as water-soluble pucks, either in paper bags of 5 kgs each or in big bags of 400 kgs each. Therefore, they are in particular suited for use in automated dosing systems and even better distribute in the concrete mixer. Due to the fact that production takes place in Germany, the delivery reliability is increased, transport distances are shorter, leading to greater sustainability.

As usual, Sika also provides its comprehensive services around SikaFiber Force 50 and Force 60. Customers can rely on correct structural calculations, reliable supplies as well as the competent application technology of the market leader in concrete admixtures. „With SikaFiber Force 50 and Force 60, Sika has not only created a cost-efficient and effective alternative to conventional steel-reinforced concrete, but, as a full-service provider, we also provide our customers with a real added value when it comes to service,“ states Peter Löschnig, Market Field Manager Concrete Admixtures.

Dutch manufacturer of precast concrete elements convinced

The Dutch Holcim Prefab Wanden B.V. precast concrete plant has been a leader in the field of precast concrete production since 1985. The precast concrete elements produced by them are used in various building types – from the single family home to the commercial building.

For a short time now, the company has been using SikaFiber Force 50 for the manufacture of its products and is convinced of the capabilities of the macro polymer fiber: Apart from the reduction of steel reinforcement and the related cost savings, the ease of application and the enhanced concrete performance, the precast producer, in particular, praises the savings in terms of material and labor costs, enabled by the polymer fiber. All in all, the use of SikaFiber Force 50 results in a significantly increased productivity at Holcim Prefab Wanden B.V.

CONTACT

Sika Deutschland GmbH

Kornwestheimer Str. 103-107

70439 Stuttgart/Germany

+49 711 8009-0