Multifunctional Formwork for Plate-Shaped Precast Concrete Components

Concretes are becoming more and more high-performance, which in turn places higher and more diverse demands on the formwork used in the precast plant. This is the case in particular in the manufacturing of plate-shaped components – like solid walls or insulated prefabricated panels.

Increase in seal tightness

Modern, in particular fluid concretes show off their advantages through greater strength, flowability, faster curing, lower specific weight and further properties or the combination of several of these factors.

However, the increased fluidity leads to increased problems with the seal tightness of a formwork. This can affect the formwork itself, which cannot guarantee the seal tightness in steel or wood at the contact points with the formwork table and causes the concrete adhesive to be penetrated. However, the formwork table itself can also be badly worn with ridges or waves and thus no longer reliably provide the tightness to the formwork.

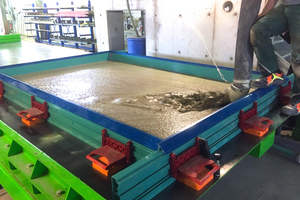

The new aluminum formwork from GMS was designed with the object of overcoming this problem. This means demolding a precast concrete component at the end of the production proc-ess that does not leave any concrete residue on the formwork table. This shortens the cleaning time of the formwork table as well as the formwork itself and increases the quality of the precast component.

Thus even heavily worn formwork tables can continue to be used, because the seal in the formwork compensates for the unevenness of the table and thus provides a fully functional system of formwork and formwork table.

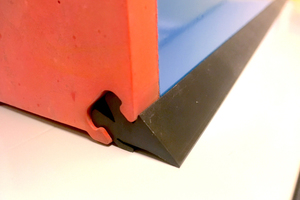

This design problem is solved by a rubber seal that is positively locked in the aluminum formwork. The rubber seal can be easily removed at any time for cleaning or replacement and then inserted again with a couple of steps.

Modular formwork system

The formwork system consists of a light aluminum formwork profile with a base gasket, cap and magnet. This formwork profile comes supplied in a standard length of 5.80 m. The indentations and elevations on the profile have different functions that define the profile and thus make it useful.

The indentation on the underside receives the rubber seal already discussed. On the topside, there are two bulges that fix the cap strip and thus specify the variable height of the profile.

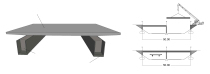

An indentation is used to join the formwork. The profile connector can be moved at will in this indentation, and correspondingly positioned it positively connects two profiles. Hence, if required the formwork can also achieve lengths of up to 12 m. Finally, there is an indentation on the rear of the profile that, in combination with the magnet secures the aluminum formwork on the formwork table.

The formwork is available in heights of 100 mm to 300 mm, wherein the height difference is in each case 25 mm. The heights in between can be set in increments of 5 mm each, to this end the formwork caps are exchanged.