Monitoring fresh concrete by means of mobile moisture measurement technology

In real-life application, problems repeatedly arise during the execution of concrete structures due to an excessively high or non-uniform water content in the fresh concrete mix. For quality assurance purposes, it would therefore be of advantage to reliably detect and limit variations in the water content during the pouring process.

Checking the water content of fresh concrete by means of the kiln-drying method is time-consuming and is only done in exceptional cases.

There have to date been no findings from systematic scientific investigations aimed at establishing the applicability of such measuring instruments to concrete.

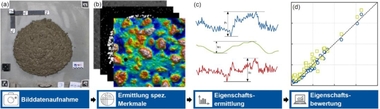

During tests on fresh concrete carried out in the laboratory of the TH Köln (University of Applied Science) and on the construction site, a hand-held probe with microwave technology was evaluated in terms of concrete-technological factors influencing the measuring result.

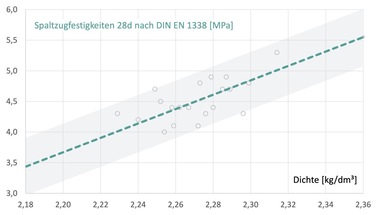

A concrete of strength class C25/30 with soft consistency was chosen as a reference. Proceeding from the reference formulation, concrete-technological parameters such as the water-to-cement ratio, type of cement used, cement content, grading curve, maximum particle size and type of concrete admixtures used were varied in the laboratory.

The results suggest that, under specific concrete-technological boundary conditions, the mobile moisture probe is generally suitable for quickly detecting, evaluating and documenting the uniformity of successive concrete deliveries in terms of their water content. Furthermore, it can be stated that the measurement results or calibration details of a specific concrete formulation cannot be readily transferred to a second formulation.