Mesh Spacer und Insert Placer: automated to higher efficiency

Against the background of ever-increasing cost and time pressure in the manufacturing industry, efficiency improvements are part of the success recipe to prevail on the market. The same applies to the precasting industry. Innovative automation concepts make it possible to speed up and improve the quality of previously manual work steps. An example of this is automated installation of spacers and inserts. For this, Progress Maschinen & Automation, a company of the Progress Group, has developed two future-oriented systems.

That the degree of automation in precast plants has massively increased in recent years is no accident. More and more work steps that were previously performed manually – and were therefore cost-intensive and susceptible to error – have become obsolete. Not only efficiency has been increased, but in many cases the quality of the end product as well.

Following automation years ago of the shuttering process and of the installation of reinforcement and embedded parts in the manufacturing of precast products, there remained two work steps at the beginning of the production cycle that still had to be performed manually: installation of spacers for the wire mesh reinforcement and the placing of inserts.

Automated installation of spacers based on CAD‑CAM data

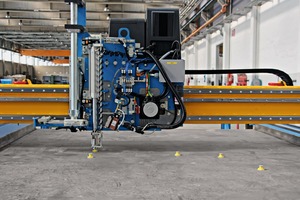

The spacers for wire mesh mats were previously installed manually in the form of rings, plastics strips, or spacer bars. With the aid of a special solution, the Mesh Spacer, these elements can be replaced by special spacers and positioned on a production pallet fully automatically by a robot system.

During production, a positioner takes the required number of spacers from the magazine and places them on the positions defined by the CAD-CAM data. The optimal position is calculated with the system’s own algorithm and monitored by an integrated laser system. In this way, uniform concrete cover can be ensured.

Quality improvement and significant cost reduction

Automation of this work step not only results in reducing the number of spacers to a minimum, but at the same time improves the quality of the precast product. In addition, it increases cost-efficiency: the savings potential, according to calculations by Progress Maschinen & Automation, ranges at up to 20 cents/m². Assuming an annual production of 500,000 m², savings of 100,000 euros can be easily realized with the Mesh Spacer.

Automation of the installation of inserts enables similar advantages: the robot called Insert Placer separates, glues, and positions inserts such as threaded inserts. These are needed for attaching service pipes to precast floor slabs. The type of pipe can be designated by various colors. During installation, this enables instant recognition of exactly where water pipes or electric conduits must be fixed in place.

Fast and accurate

Both sorting and readying the inserts and refilling the cartridges are fully automated. The cartridge itself can also be automatically and quickly exchanged – for example for changing the color. An integrated glue gun applies glue onto the pallet prior to positioning the threaded inserts. The inserts are positioned in accordance with the CAD-CAM data transmitted. The entire procedure takes place within a matter of seconds per insert.

The fully automatic systems – both the Mesh Spacer and the Insert Placer – are already in use in precast plants worldwide. The Mesh Spacer, moreover, was installed in a precast plant owned by Progress Group. The new solutions complement a range of innovative automation concepts developed by Progress Maschinen & Automation.