Joint venture for the production of glass fiber reinforcement

Schöck AG, the industry specialist based in Baden-Baden, Germany, and Fiberline Composites A/S, Middelfart, Denmark, start a joint venture. Purpose of the undertaking is the further development and production of glass fiber reinforcement for various products of Schöck. The intention of both partners is to boost the use of glass fiber technology in the construction sector.

The companies join their competencies and the know-how gained over 15 years in co-operating and further developing of glass fiber reinforcement. Schöck has a share of 75 % in the joint venture and Fiberline holds 25 %. General Manager of the new company is Thomas Stürzl. Within the strategic alliance, Fiberline provides manufacturing and process know-how and is responsible for purchasing and process technology. Schöck is concentrating on production, further processing and marketing.

The partners will join forces to strengthen the development of the products. The new company will be based in Halle an der Saale, where Schöck has so far been manufacturing products and components made of concrete and plastics. The production of glass fiber reinforcement will start in the in 2019. Until then, the production will take place at Fiberline in Denmark.

High reliability

“With the joint venture Schöck secures the innovative manufacturing technology of Fiberline for the production of glass fiber reinforcement, thus having direct access to the key technology,” states Dr. Harald Braasch, Chief Technology Officer at Schöck. For the customers of the German supplier to the construction industry this means that they will also in future get products with glass fiber components in high quality and supply reliability as they are used to from traditional construction products made of steel and stainless steel. Whereas Fiberline can focus on optimizing its production and increasing the benefit for its customers.

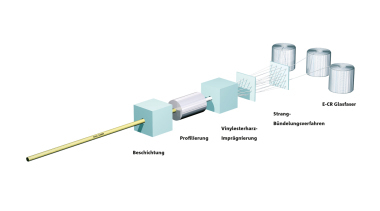

The joint venture is a response of the two partners to a growing demand for glass fiber technology in construction. The material impresses with its particular properties. It is corrosion resistant, resistant to chemicals, electrically non-conducting and easy to machine. The low thermal conductivity of λ = 0.7 W/mK in comparison to reinforcement steel (λ = 60 W/mK) and stainless steel (λ = 15 W/mK) promises particularly great benefit. The new material enables contractors to fulfil the rising standards in respect of energy-efficient construction (EnEV - German Energy Savings Regulation, passive house standard) without any problems. The glass fiber reinforcement not only contributes to save energy in buildings, but also makes a sustainable contribution to climate protection in the production process. The CO2 emissions are much lower than in the production of conventional reinforcement steel and stainless steel.

Co-operation over many years

The co-operation between Schöck and Fiberline dates back to the year 2000. In four years of joint development work, Fiberline was able to improve its manufacturing processes for the production of reinforcement products. “At the end of the development project, there was a product setting new standards in terms of mechanical strength and corrosion resistance. The joint venture will allow us to place this product on the market even more widely,” says Peter Thorning, CEO of Fiberline.

As the first company, Schöck was granted with a German national technical approval for glass fiber reinforcement in 2008. In 2010, this was followed by the approval for the Schöck Thermoanker featuring the same material technology. In 2017, Schöck presented the global innovation of Isokorb XT Combar with tension members made of glass fiber reinforcement.