Higher productivity and component quality with laser projection

Precast concrete parts factories must produce large quantities of the same quality in an ever-shorter time. Manufacturing tolerances in the production of wall elements, ceilings or double walls must be precisely adhered to. Even in highly automated manufacturing, parts are still placed manually on pallets.In order to meet the demand for high component quality and cycle times, more and more plants worldwide are implementing laser projection systems. These systems eliminate the need for manual measuring by means of a tape measure and optimize efficiency throughout the entire production cycle.

Increased efficiency at every workstation

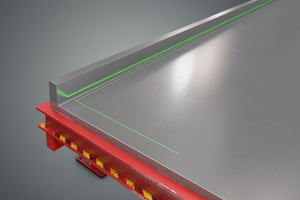

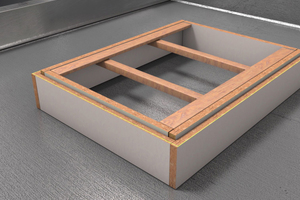

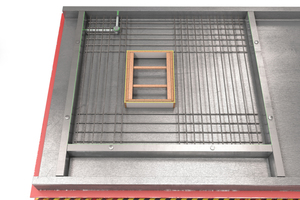

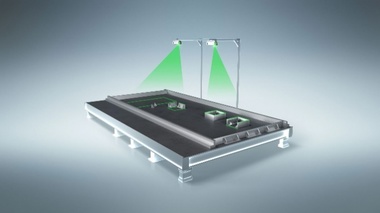

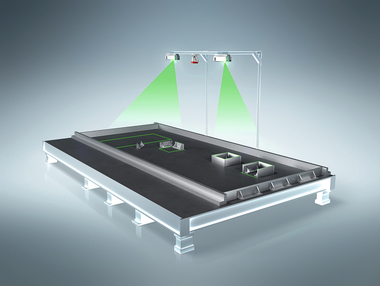

As a laser technology specialist, LAP produces laser projection systems for the world market, which are used in diverse manufacturing industries. The Concrete PRO solution has been specially optimized for the requirements of the precast concrete industry. LAP laser projection systems are used at various workstations, ranging from placement of formwork, positioning of components and display of cut-outs to placing reinforcements. Finally, they also check the presence, correct positioning and orientation of all elements before filling with concrete. This is especially relevant for double wall production in order to ensure that, on the one hand, each wall fits properly to the other half and that, on the other hand, reinforcing bars or mounting parts do not collide when joining.

Quick, precise placement of all elements

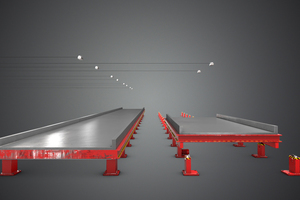

Where every second counts, laser projection saves valuable time: Based on CAD data, CAD-PRO laser projection systems display the precise location of all elements. In a typical application, they project the outlines of cut-outs from a height of 5 to 10 meters onto a fixed table/flat bed/deck or a carousel pallet. The operators can position all elements precisely. A manual basic calibration of the system is only required once during installation. In daily use, calibration can be conducted automatically and within seconds at any time.

Minimal training time

The LAP software PRO-SOFT 5 controls the entire workflow: from importing projection data from CAD programs, calibration and visualization of projection steps, to documentation. The software also takes into account different heights of the components and visually compensates for such differences. Another important benefit: Only minimal training is needed to operate the projection system. The user interface of the software is intuitive and user-friendly. Important functions can also be directly accessed by remote control.

Close collaboration with system partners

The entire system is scalable and can be configured for each plant type to application-specific requirements. LAP maintains close

collaboration with equipment

construction companies and software companies in this field to ensure easy integration and

implementation into your factory. The software is compatible with all known master computer systems (such as Unitechnik, RIB SAA, Progress etc.) with common data formats

such as DXF, HPGL, Unitechnik

4.0-7.0 and UXML.

Laser projection systems worldwide

Numerous installations on four continents speak for themselves. LAP laser projection systems are used throughout production facilities in Europe, China, the USA and Australia among others. Currently installed systems range from carousel plants to plants with fixed tables /long decks/flat beds with up to ten projectors covering a workstation.

Reduced lead times increase productivity

Mostly, saved time speaks for the use of laser projection as increased productivity and thus reduced costs mean being ahead of the competition. With all elements placed precisely on pallets or tables/beds/decks laser projection also contributes to a constant product quality. Compliance with production tolerances down to millimeter accuracy can ultimately prevent claims.