A new solution for installation at the precast plant without tools

In cooperation with manufacturers of precast concrete elements, Spelsberg, the specialist in enclosures, has developed a new system which significantly facilitates electrical installation when it comes to horizontal precast production. The new Precon series has been furnished with a lot of new details, accelerating installation works considerably and rendering re-working unnecessary.

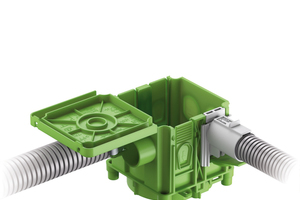

Now, it has become particularly easy for the user to insert conduits. After breaking out the pre-punched areas by a slight blow on a screwdriver, the conduit can be inserted. The actual combi-conduit entry points are placed outside the enclosure, stopping the conduit by a snap-in edge positioned inside quite automatically as soon as it has reached the correct position. In this way, the installation space is kept totally free and re-working is no longer necessary, keeping the installation effort within the scheduled limit. The strain relief is ensured simultaneously by a reliable lock, so that the conduits securely remain in their position even when pouring concrete into the formwork and during the compaction process, excluding any defects right from the beginning. Thanks to the tongue-and-groove principle used here, the enclosure is absolutely tight when wiring the individual boxes as many tests carried out at the factory have shown, where the snap-in edge prevented any concrete from ingressing inside.

Variable installation without the need of tools

Besides this method of insertion using an integrated conduit stopper, there is also the possibility to use conduit adapters and to place them variably on the box, as requested. In this regard, the engineers of Spelsberg were particularly creative and managed to design this version for installation without the need of tools, too. For this purpose, small easy-cut membranes were integrated on different spots of the enclosure. The conduit adapters can be fixed manually here by pushing the adapter from the top downwards to the membrane. The area cut in this way unfolds to the outside and the conduit adapter fits in the place. It snaps in, tightly closing the opening created. This is done in a matter of seconds, without tools and not requiring great force. The conduit adapter is also fitted with an edge inside, into which the conduit snaps in firmly, being fixed in the perfect position. The installation space remains free here, too; reworking is not necessary and the strain relief is ensured reliably.

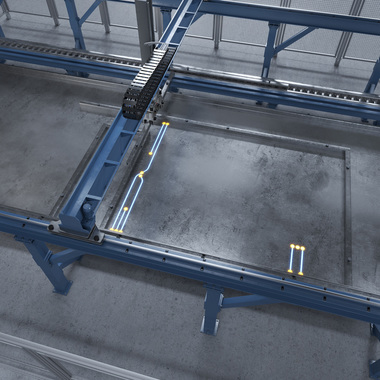

As far as the attachment in the formwork is concerned, the Precon also turns out to be a multi-talent. It can be used together with magnetic clamps and therefore the box has an open socket front, accommodating all common magnet brands without any problems and providing for an installation protected against torsion. To break out the front part is no more necessary here, and even shuttering robots are able to place the Precon fast and easily.

Numerous accessories available

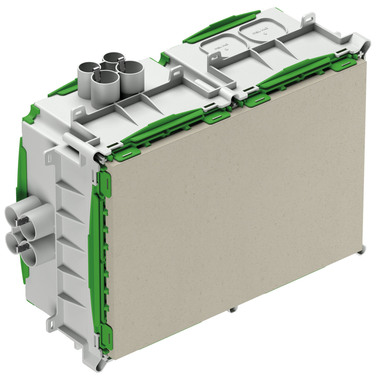

Those who relies on adhesive attachment also get the adequate solution with Precon: For this purpose, the experts have developed an adhesive front, which can no longer distort in the formwork. Its particular shape allows for flush mounting and avoids sliding backwards when applying the adhesive. To eliminate reworking for this type as well, Spelsberg has provided them with a surrounding recess, taking up surplus hot-melt adhesive. This keeps everything clean around the box and the screw bosses cannot be contaminated at all. Multiple combinations are also particularly easy to realize with Precon; as an option, the boxes can directly be combined with the aid of the integrated snap-in connections. In case of extreme load, glands available as accessories provide for maximum hold. They are available in various dimensions allowing for defined, large distances in an easy way, too.

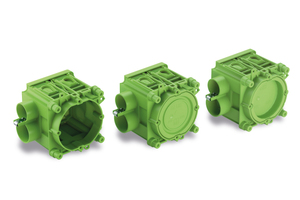

By now, the new Precon series provides three different sizes for each of the three types of attachment (hot-melt adhesive, Els magnets, magnets of other manufacturers). The range is complemented by numerous accessories such as conduit adapters, magnets or glands. A new brochure regarding these products is available for download on the home page of Spelsberg, a corresponding sample kit can be ordered likewise.