3D printing of built-in parts – digitization boost for

concrete plants

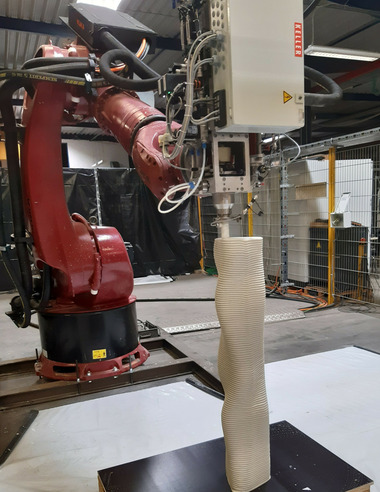

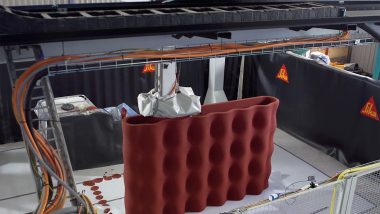

In the rapidly developing world of 3D printing, the 3D printers from Kühling&Kühling GmbH show how this new technology can also give traditional production techniques a digitalization boost. As an innovative developer and manufacturer of industrial 3D printers from northern Germany, the company has made a name for itself with various industry solutions and is now also focusing on the precast concrete industry. Its versatile 3D printers process all thermoplastics that are of central importance for the production of built-in parts and recess formers in the precast concrete industry.

Success story of 3D-printed recess formers

Kühling&Kühling‘s partnership with Oskar Heuchert GmbH & Co. KG, a precast concrete plant in Trappenkamp, played a decisive role. This cooperation enabled the implementation of several reference projects and provided the opportunity for direct feedback from the field. „The close cooperation helped us to develop a deep understanding of the specific requirements of the concrete industry, including the special properties of concrete as a material, the requirements of the plant processes and the handling of the products by the production employees,“ says Jonas Kühling.

An important aspect was work preparation, in particular demand planning and the ability to parallelize the production of the 3D-printed recess formers with the formwork construction. This led to a more efficient and smoother production chain.

The positive feedback from concrete workers in the field is remarkable. A recurring echo was: „Are there more of these parts, or do I have to go back to the band saw?“ The 3D-printed installation parts were also praised for their precision and ease of installation and, according to the manufacturer, represented a significant improvement over traditional methods in the practical test.

Increased efficiency even without 3D modeling experience

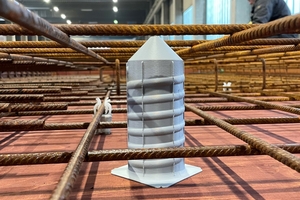

The main advantages of Kühling&Kühling‘s 3D printers in precast concrete production are their efficiency and adaptability. Fully automated 3D printing enables the production of built-in parts without manual labor, significantly reducing the need for man-hours. Hand-cut polystyrene foam cores or rusty, sharp-edged sheet metal pipes belong to the past. In contrast to purchased catalog parts, the dimensions of all components can be individually adjusted ensuring all parts correspond exactly to the geometries as specified in the factory plan.

This is made possible by a specially developed component configurator, which can be used to create tried-and-tested built-in parts such as corrugated tubes according to desired dimensions and without the need for in-house 3D modeling experience - including exotic special sizes from a quantity of 1. As a side effect, stock levels can be significantly reduced as the components can be manufactured just-in-time for production.

Response to the shortage of skilled workers and incentives for young talent

In addition to process optimization, the two factors digitalization and automation, as promoted by Kühling&Kühling for its customers, also address two key challenges in the construction industry: a shortage of skilled workers and the attractiveness for young employees. The use of advanced 3D printing technology reduces dependence on manual labor and attracts young people who are enthusiastic about digital innovations and automated processes.

This can make the industry more appealing to the next generation of workers and provide pathways to a career in a technologically evolving environment. Jan Heuchert, Managing Director of Oskar Heuchert GmbH & Co. KG, emphasizes that „the scarce wage hours are better used in the core processes around concreting and formwork construction than in tinkering with recess formers.“

A vision for the precast concrete industry

Kühling&Kühling has a clear vision for the future of the precast concrete industry: to actively shape the digital revolution at the production level with its printers. At a price below that of a small car, the current printer model, the „HYBRID 1“, is affordable for almost every concrete plant and thus enables entry into the future technology of 3D printing. The digital component catalog of printable built-in parts, which is available to all customers and is constantly being expanded, makes it possible to use the printers in productive operation even without in-house expertise in 3D modeling.

CONTACT

Kühling&Kühling GmbH

Ricklinger Straße 2-6

24610 Trappenkamp/Germany

+49 431 98352473-0