Ratec: Annual Report 2018

28.03.2019

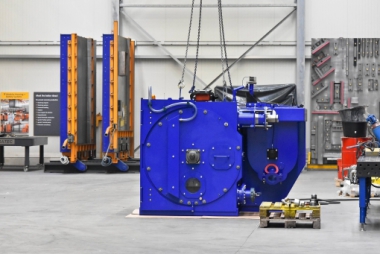

In 2018 at Ratec more built-in magnets were integrated into formwork than ever before (Figure: Ratec)

In 2018 at Ratec more built-in magnets were integrated into formwork than ever before (Figure: Ratec)

In terms of sales and earnings, Ratec can once again look back on an exceptionally successful year in 2018. The driver of this success was the international business with an 84 percent share of sales. Germany accounted for 16 percent of sales.

The largest non-European market in the past year was China, where 23 percent of sales were generated. But the company also benefited from lively demand in the booming construction markets of other Asian countries such as Malaysia, the Philippines and Singapore. It is not without reason that Ratec has been represented in the region since 2017 with its own branch office – Ratec Asia located in Singapore. Asia contributed 41 percent of sales (previous year: 39 percent).

In the European Union, where 34 percent of sales were generated (previous year: 36 percent), the focus was on Austria, the Netherlands, the Benelux countries, Denmark as well as on Poland and France.

Business in the United States was stable. Here, with its own subsidiary, Ratec offers special products for the North American market in addition to its broadly diversified standard program. In the past financial year, a complex battery system was manufactured, installed and successfully put into operation for Jensen Precast, one of the largest manufacturers of precast elements in California.

Ratec now supplies customers in more than 80 countries.

Quality remains the key to success.

Ratec continues to rely on a high degree of its own vertical integration, only in this way can the exceptionally high quality demands on its products be secured over the long term. In the past financial year alone, more than 100,000 neodymium magnets, produced by the company’s own magnet factory in Solingen, were integrated into Ratec formwork components. Ratec stands for Made in Germany like no other provider in its segment. That’s why the company is investing in the certification of its QM system in order to demonstrate its strict quality demands also in accordance with international standards.

New concepts are revolutionizing modular construction

Outstanding project success related in the past year to the development, manufacturing and commissioning of an innovative modular formwork for the production of substations. Exchangeable caps that are securely held at the core with hydraulic clamping fixtures allow the customer to produce a wide range of variations – and that with reference times of just a few minutes. In Singapore, a newly-developed modular toolbox with a shrink core was successfully put into operation. Inside and outside formwork makes it possible to adapt to various room dimensions so that a modular construction is worthwhile already with small quantities.

Intensive product development as further important success factor

The always intensive product development in the area of magnetic formwork technology was continued. A series of new developments were made market ready in 2018 including, for example, a shrinkable window and door box-outs or a customer-specific solution for the production of supports and beams. Other standard products were updated and developed further. Particularly intensive development work was conducted in the area of room module formwork for volumetric elements, the results of which will be presented to a broad professional public at the bauma, which will take place from April 8 to 14 in Munich. Visitors can look forward to new, sometimes groundbreaking solutions from Ratec (Hall B1, Number 348).

Trade fairs as a focus of marketing and sales activities

Once again in the past year the most important marketing and sales instrument was the presence of the company at all important international trade fairs. The motto in this regard is always the same: Meet the better ideas in precast and modular construction. Wherever possible, Ratec also helps to give new impetus to the topic of precast construction by contributing its own presentations or workshops.

Optimistic outlook for 2019

On the basis of pleasing orders received and a very sound order backlog, Ratec expects a continuation of the growth course and again good earnings in 2019. With the ongoing development of its magnetic formwork technology and pioneering formwork solutions for modular construction, the company intends to win new projects, primarily in the international environment.

Ratec enters the 25th anniversary of the company in 2019 which will be celebrated in the second half of the year – with due thanks to its customers and its employees.

CONTACT

Ratec GmbH

Karlsruher Straße 32

68766 Hockenheim/Germany

+49 6205 9407-29