Use of Paschal “modular universal formwork”

Paschal-Werk G. Maier GmbH, normally being the supplier of concrete formwork systems, this time is the recipient of the same: the construction company Werner Ritter (Schuttenwald/Germany) pulled down an old building on the premises of the company headquarters, in order to build there a modern factory and storage building measuring about 20 x 40 m. Of course, using formwork of Paschal.

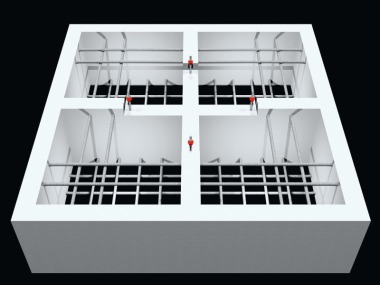

Having removed the old foundation, the native metal foundation as well as the old backfill, new foundations could be bedded. They consist of single foundations positioned in a row up to 4 m deepened into the soil, in the course of which the top level of groundwater in summer was just touched.

The foundations have been built by means of the universal formwork modular. For the load-bearing walls the wall formwork LOGO.3 was used. The front part of the building is covered over with a roof; at this part a heavy-weight, track mounted gantry crane will be installed.

The base sockets assimilate the precast concrete components of a height of 7.90 m. Between the same walls will be brought up. These 24 precast components are forked at the top edge and just before the bifurcation there is a small overhanging console. Usually, such kind of precast concrete components are ordered ex factory, explains foreman, Werner Sachs, who has acquired his master certificate in a precast concrete plant. For such a procedure the lead time, however, was insufficient. Consequently, the wall formwork Logo was used without hesitation, as it happens as well in some precast concrete plants, adding some intermediate layers, and the formwork was ready. Placing several molds side by side, it was possible to fill them with concrete just in a row, when the concrete mixer truck was at the construction site anyway, for example to cast foundations. The weight of each precast component is about 6.5 up to 7.2 t. Each of them got a number and a storage place, as to wait compactly stored until September 8, 2008. Finally it was possible to position all of the components by means of a crane on one working day.

Address/Anschrift

Paschal-Werk G. Maier GmbH

Stammwerk Steinach

Kreuzbühlstraße 5

77790 Steinach/Germany

Tel.: +49 7832 71-0

Fax: +49 7832 71-209

service@paschal.de

www.paschal.de