Pallets for Israeli concrete products manufacturer Block America

“During the last bauma in April 2019 in Munich we discussed with Mywood Sales Director Tobias Schmidt about several production pallet options which harmonizes even better with our requirements and the production requirements in comparison to our pallets we had in use that time”, remembers Harel Milstein, the owner and Yosef Rada, the technical of the company Block America in Israel. Block America is the leading developer and producer of architectural concrete masonry blocks and veneers in Israel.

Above all, it was important for us to find an alternation with which we can produce our sophisticated and high-quality concrete products in good quality. The first communication about was very detailed already and in a next step the companies agreed to send a number of test pallets to the Block America plant to see how the UPadvanced pallets behaves in practise and under the harsh conditions in Israel. The experience after the tests was excellent and Milstein and his team had the impression relatively quickly that the UPadvanced would be the right choice. Later in the year the next meeting took place together with the Mywood sales representation in Israel, company Pumice (represented by Oren Zisman and Alex Blumenfeld), directly in the plant. The main target there was to identify before placing final order potential risks in the cycle which may mechanically damage the pallets. Block America is producing on a Henke Variant machine with a closed rack system - so prevails for instance curing conditions in the rack system of around 70-80 % moisture content. Finally, Mywood delivered by beginning of 2020 a whole new set of production pallets UPadvanced to Block America.

Harel Milstein is mostly happy about the technical input he has got through the test period, before and after the delivery of the production pallets. The combination between our own ideas and the recommendations from Mywood and Pumice have complemented each other perfectly, says the company owner with satisfaction. Some adjustments regarding maintenance and transport system in the production cycle were made, to create the ideal conditions. After it was done, we were ready to implement the new production pallets in our cycle.

Three years of use without problems

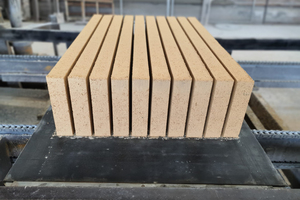

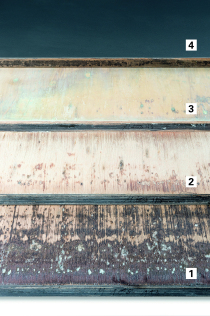

After nearly 3 seasons of the pallets in use Block America is very happy with the decision. The advantages and characteristics of the UPadvanced which we were hoping for have been 100 % confirmed. „A production pallet with very good static behaviour and a strong surface without joints - this are reasons that we can say with full conviction that we met a very good decision in 2019“, Milstein summed up his impressions. „The UPadvanced is a true all-rounder. “Because of the completely closed surface easy to use for both thin and large size products. Suitable to produce heavy and high products in very good quality, because the pallets show only little bending at very height weight loads. Very important for the client was to invest in a pallet on which he is able to assign products in different formats easily.

It is the intention of Mywood to offer its customers a high-quality product at an attractive price level. „Using wood with mainly standing annual rings in the core gives more stability to the board. The E-modulus is 12.700 N/mm² and thus much better than most pallets available on the market. The plastic covering ensures that the bottom of the final products is smooth and flat “, says Mywood Sales Director Tobias Schmidt. This excellent E-modulus was also the main reason why it was possible for Block America to reduce the pallet thickness from 50 mm before to only 45 mm with the investment in the UPadvanced. The very good stiffness and vibration transfer of the pallet leads to very positive results regarding the compaction of the concrete products. The cycle times were reduced in average for more than 10 % in comparison to the wooden production pallets which were in use before. Due to the aforementioned, in relation low weight, UPadvanced pallets are easy to handle and the machine is significantly less stressed in comparison to more heavy pallets.

CONTACT

MyWood Polomka Timber s.r.o.

Osloboditel´ov 50

97666 Polomka/Slovakia

+49 9853 3855 521