Innovation: WAM Duplocon

As part of the BetonTage trade fair, the Innovation Award for the Concrete Component Supply Industry will be presented on 10 March 2026. On the following pages, we present the first part of the innovations submitted, which make production and construction processes in the precast concrete industry more efficient and economical. The prize is awarded jointly by FBF Betondienst GmbH and the trade journal BFT International – the award recognises particularly creative and practical solutions that are of great importance for the core processes of the precast concrete industry. In issue 03/2026, we will present the second part of the innovations. Stay tuned.

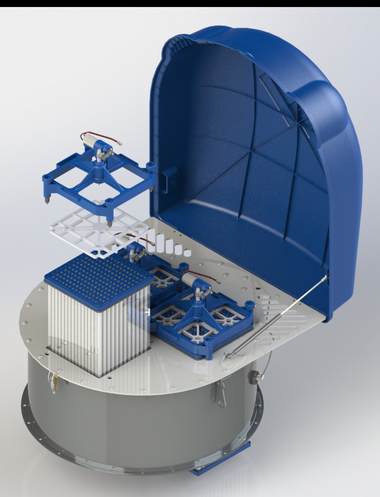

Duplocon – The compressed air-free discharge system for cement

Rising energy costs are increasingly posing economic challenges for manufacturers of concrete products. The generation of compressed air is one of the biggest energy consumers in concrete production. Against this backdrop, the WAMGroup is pursuing the goal of fundamentally changing silo systems – by eliminating compressed air and improving energy efficiency throughout the industry.

Innovation and technology

Duplocon is a mechanical discharge system for the efficient discharge of cement from silos in concrete and dry mortar plants. It marks a decisive step towards compressed air-free silos. Building on the WAMGroup‘s many years of experience in the fields of screw conveyor technology, dust extraction, shut-off technology and silo safety, Duplocon combines proven components – such as the Silotop PolyTube filter, which is cleaned mechanically without compressed air.

The patented Duplocon system uses an external vibration motor to discharge the cement mechanically. This ensures uniform and continuous discharge across the entire fill level – without the need for compressed air.

Advantages for industry

In addition to reliably preventing flow disturbances such as bridging or chimney formation, the Duplocon scores points with its compact design. The low height also reduces the overall height of the silo, which allows for additional flexibility in plant design. The uniform material flow also increases the efficiency of downstream screw conveyors and shortens the feeding times of the mixer – for a smooth and economical production process.

Sustainability

The elimination of compressed air in cement discharge significantly reduces energy consumption and CO₂ emissions. Duplocon thus makes an important contribution to resource-saving and sustainable concrete production – in line with increasing environmental standards and corporate sustainability goals.

Economy

As there is no need for energy-intensive compressed air, operating costs are significantly reduced. In addition, the design facilitates installation and maintenance, minimises downtime and increases plant availability. Duplocon is therefore an economically attractive investment, offering both immediate energy savings and long-term operational benefits.