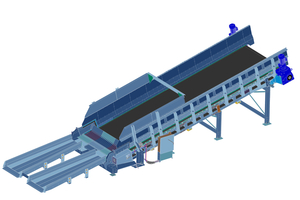

Innovation: VHV BigFeeder

The BigFeeder is the innovative solution for fast, clean and efficient loading of conveyor systems with bulk materials. Thanks to its sophisticated design, it replaces costly pits, fault-prone grates and complicated dosing systems – ensuring a smooth flow of material with minimal maintenance.

The advantages at a glance

Direct loading without intermediate stages – no grates prone to clogging or disruptive layer height sliders.

Maximum operational reliability thanks to the Dynamic Belt Sealing (DBS) system – tight, robust and low-maintenance.

Space-saving & flexible – no pits required, easy integration.

Economical and maintenance-friendly – standardised wear parts, low operating costs.

Versatile variants – with hydraulic folding ramp or ramp extension.

Technical highlights

Belt width: 3,000 mm

Incline: 13° – ideal for a wide variety of bulk materials

Conveyor capacity: 80–2,000 m³/h (speed-controlled via frequency converter) per truck 23 m³/40 t

Discharge time after tipping approx. 35 seconds

Drive: 2 × 15 kW gear motors, controlled via frequency converter (37 kW)

Centre distance: 10,000 mm

Hydrodynamic belt tension for smooth running and high durability

Well thought-out process – from loading to unloading

The lorry reverses onto the BigFeeder, tips the material and unloads it safely onto the conveyor belt. Sensors measure the layer height and automatically regulate the belt speed – for uniform feeding of downstream systems. An integrated weighing function is available as an option for precise recording of the entire lorry load.

Ideal for demanding material flows

The BigFeeder is the perfect solution for companies that value reliability, speed and cost-effectiveness – such as recycling plants, building material factories, quarries or the energy and waste disposal industry. With the BigFeeder, you are investing in modern conveyor technology that redefines efficiency and ease of use – robust, safe and durable.

CONTACT

VHV Anlagenbau GmbH

Dornierstr. 9

48477 Hörstel/Germany

+49 5459 9338 0