Innovation: Cleanjet

Automated high-pressure cleaning for greater safety and efficiency in the concrete industry

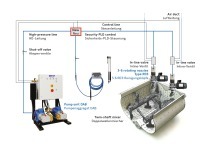

With its Cleanjet systems – in particular the Cleanjet 1500 and the Cleanjet 2-in-1 – Walter Cleaningsystems has developed a pioneering solution for the automated cleaning of truck mixer drums that fundamentally improves existing processes. The innovation is particularly notable for the complete elimination of manual chiselling and dangerous drum access – a quantum leap in occupational safety and a significant contribution to process reliability and cost-effectiveness in concrete plants.

A revolution in safety – cleaning without physical strain and risk

The manual removal of hardened concrete from the mixing drum involves considerable risks: falls, falling concrete parts, forced postures, dust exposure and confined spaces are among the typical risk factors. Cleanjet replaces this risky practice with a fully automated system with 1500 bar maximum pressure technology. The cleaning system is programmed once for the drum type (teach-in) and then carries out the cleaning process without anyone having to be in the drum or near the opening.

Technological progress – efficiency and precision through robotics

Cleanjet systems are robot-controlled. The cleaning nozzle follows the inner contour of the drum precisely and efficiently removes both fresh and hardened concrete residues. The Cleanjet 2-in-1 model combines medium-pressure cleaning (220 bar) for daily cleaning with an integrated maximum pressure option (1500 bar) for periodic intensive cleaning – in a single system. This not only optimises the cleaning process, but also increases the availability of truck mixers and reduces operating costs.

Contribution to compliance with legal requirements and prevention

By completely eliminating manual intervention, Cleanjet technology meets key requirements for modern occupational safety (e.g. TRBS 1112 Part 1 – Working in confined spaces) and supports companies in designing their operational processes in compliance with legal requirements. At the same time, it strengthens the safety culture in the workplace and reduces absences due to illness caused by physical overload.

Successes achieved in practical use

No more need to enter the drum reduction in serious accidents

No more chiselling work required elimination of physical strain

Plannable cleaning intervals higher machine availability

No manual control necessary during cleaning

Positive feedback from practical use regarding efficiency, safety and user-friendliness.

Conclusion

Cleanjet is a truly key innovation for the concrete goods and precast concrete industry: it replaces one of the most dangerous activities in concrete plants with a safe, automated and economically attractive solution. With its focus on prevention, technological excellence and sustainable process optimisation, Cleanjet makes an outstanding contribution to the further development of state-of-the-art technology.

CONTACT

Walter Gerätebau GmbH

Neue Heimat 16

74343 Sachsenheim-Ochsenbach/Germany

+49 7046 9800