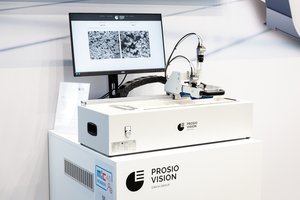

Innovation: AI-based in-line detection of particle sizes

Prosio Vision GmbH, a company of the Eirich Group, has developed the VC series (Vision Control), a modular system for the automated detection and analysis of material properties in concrete product manufacturing. The solution combines industrial image processing with AI evaluation to continuously and objectively record parameters such as particle size distribution, grain shape, surface structure, and plasticity. Unlike conventional methods, data is collected in real time directly during the process. The results are not only documented but also used for process control—as a basis for data-driven optimization and even self-regulating production systems. The VC series improves processes and services in several dimensions:

Process reliability and quality: Continuous, sensor-based recording of material properties replaces subjective visual inspections and discontinuous laboratory analyses. This increases reproducibility and reduces waste and rework.

Resource efficiency: Precise control of mixing and production processes allows raw materials to be used in a more targeted manner. This contributes to a reduction in material consumption and energy use.

Digitalisation and data availability: The systems can be fully integrated into digital production environments. They enable seamless documentation, remote access and the use of process data for predictive maintenance and quality assurance.

Adaptability: Modular architecture for flexible integration—from laboratory applications to series production.

In addition, the technology opens up new possibilities for research and development in building material optimization: objective, high-resolution recording provides a reliable database for evaluating formulations and their influence on product quality—for industrial applications as well as scientific studies. The VC series thus contributes to increasing process intelligence and establishing data-driven production strategies. It represents an important step towards Industry 4.0 and contributes to the sustainable, efficient and quality-oriented manufacture of concrete products. Initial practical experience was gained in use cases for incoming goods inspection. This demonstrated that the systems are capable of reliably recognising grading curves from image data. This information enables automated classification of the delivered material and differentiation between good and rejected goods. The application in goods receipt demonstrates the potential of the technology for early quality assurance and for avoiding defective batches even before processing.