Far more than a digital magnifying glass - quality assurance as an integral part of the intelligent Masa plant control

More than control – true process intelligence: By fully integrating optical quality control into the Masa plant control system, a solution has emerged that not only monitors quality but helps ensure it and sustainably increases efficiency.

Fully automated, optical Quality control systems are becoming increasingly established in the block and paver manufacturing industry. However, Masa is going one step further with its system introduced in 2025: the combination of high-resolution image processing, 3D surface inspection and artificial intelligence is not used in isolation, but is seamlessly integrated into the Masa plant control system. The result is a system that not only provides monitoring, as many competing products do, but also enables operators to intervene quickly in the production process and optimize it by linking the device to all plant data.

Masa‘s integrative approach combines image processing, process data and control logic into an intelligent overall system. At a time when production processes are becoming increasingly complex, quality requirements are rising and flexibility is becoming a decisive competitive factor, existing staff must also be optimally supported. This calls for a new way of thinking. The key lies in technology that both monitors quality and combines human capabilities with precise digital support, thus becoming a real game changer.

Quality control: Precise sensor technology for defined quality

Quality control demands a trained eye -precise, consistent and reliable. At bauma 2025, Masa presented its technical solution for automated, optical quality control that meets precisely these requirements:

Positioned directly behind the production machine on the wet side, the system performs contactless measurements on freshly manufactured concrete products in-line – without interrupting the production flow. While the production board with the products is continuously transported onwards, the system records precise measurement data in real time.

Operators can define tolerance limits according to requirements and product specifications. The system detects a wide variety of product defects and distinguishes, for example, between actual surface defects and contamination.

All detected exceedances of the set tolerance limits are visualized and classified in the Masa plant control system, and the affected products are clearly marked. In addition, the system measures the product heights across the entire production board and displays the height profile graphically – color-coded according to the defined tolerance ranges. When combined with optional weighing devices, the system calculates the average bulk density of a stone layer, thus providing valuable information about product quality.

One system, one interface, full control

Masa adopts an integrative approach in its plant control concept. For this reason, the Masa optical quality control system for new plants is fully integrated into the Masa plant control software. In existing, newer Masa plants, the system can usually be retrofitted without any problems and fully integrated into the plant control system. Integration is also possible in older Masa plants or third-party plants, but requires prior technical testing and, if necessary, a control upgrade.

Operators have direct access to all measurement results at the control station and can respond immediately if required, without needing to walk to the traditional control station. Defect images and stone height deviations can be statistically recorded and evaluated.

Standardized user interface for maximum process

reliability

For the plant operator, this means that the uniform and intuitive user interface enables efficient interaction with the entire plant as well as individual components, such as optical quality control. This applies regardless of the complexity of the respective block and paver production plant.

All relevant processes – from dosing and mixing to product manufacturing, quality control and curing to product packaging—can be controlled, monitored and visualized on any Masa control panel in the plant via a uniform HMI interface in the distinctive Masa design. This ensures consistent operating logic, high process reliability and transparent plant communication.

Detecting faults early – producing marketable

products faster

Identifying faults is the first step towards efficient production. Successful companies go further: they learn from faults and turn challenges into opportunities. This is exactly where Masa comes in with its holistic system. It not only offers precise quality control, but also opens up new possibilities for process optimization and increased efficiency.

On the wet side, the quicker the machine operator responds to product faults, the less waste is generated - and the faster saleable products are produced. When switching to a known product or recipe, the system automatically displays all corresponding parameters such as defect tolerances or product height to the machine operator. As the results of the optical quality control are displayed directly on the control panel, the operator can adjust settings immediately and achieve the desired quality more quickly.

When producing new products for the first time, the machine operator benefits from a convenient copy function within the product management of the Masa plant control software. ‘Search for and copy a similar product recipe, adjust one or two parameters, run it – it’s absolutely easy!’ says one machine operator, describing his experience of running-in a new product. ‘Our run-in time, including fine-tuning, has been significantly reduced. ’

No time-consuming teaching process is required for new products in the Masa system.

Ensuring quality with auto-stop and smart control

Experienced machine operators often take on numerous additional tasks alongside production and are not at the control station around the clock. This becomes problematic when an unplanned drop in quality occurs during a planned absence – and the production machine continues running regardless. For this case, the Masa plant control offers a configurable auto-stop function: if the quality control detects a defined percentage of defective products, the machine shuts down in a controlled manner. This avoids unnecessary waste and increases production reliability.

In addition, the machine operator can mark the production boards via the control system. Depending on the percentage of defects on the production board, this can trigger further intelligent processes:

Tilting device: The downstream Masa tilting device completely tilts the marked production board with defective products while they are still fresh, preventing them from entering the chamber system for curing and occupying storage capacity.

Marking as second-choice products: Alternatively, production boards with second-choice products can be marked. Although they remain in the ring, cost-intensive stations for surface treatment are automatically deactivated during the run.

These functions are based on the digital board ID – a central component of Masa‘s integrative control approach.

Masa Board ID instead of RFID—smart data man-

agement for production

The board ID is a unique, sequential number that is automatically assigned by the Masa plant control system to each production board as soon as it enters the block and paver production machine. Thanks to this technology, the time-consuming and costly retrofitting of production boards with digital signal transmitters such as RFID chips is completely eliminated.

Like every other process step within the production plant, optical quality control generates a significant amount of data. Data transfer between the various processing stations in the plant can be carried out using different technical solutions. Masa relies on data transfer using so-called data telegrams in combination with the board ID. Data telegrams are standardized data records that accompany the production board digitally throughout the entire plant. Logging takes place at every station where relevant process steps take place and information is generated.

The Masa plant control system can link various data sets to the board ID – ranging from simple information to complete information packages containing product data, recipes and other parameters. This also includes the log for each mixture, documented via a unique mixture ID.

Depending on the option selected, Masa thus provides detailed insights into the individual production plant:

Chamber preview – real-time quality overview for

the machine operator

The ‘Chamber preview’ function gives the machine operator a quick, intuitive overview of the quality status of the products currently in the curing chamber – in real time and differentiated by each stored production board. Each chamber position is visually displayed, showing the percentage of rejects.

Short-term benefit:

The operator can flexibly adapt the removal sequence to the current situation – for example, during staff shortages in the sorting area on the dry side.

Medium and long-term benefits:

Evaluation per production board and assignment to the respective production shift enable further analyses, such as:

Identifying fluctuations in raw material quality

Identifying training needs for personnel on specific shifts.

Ensuring product quality with data-based final

inspection

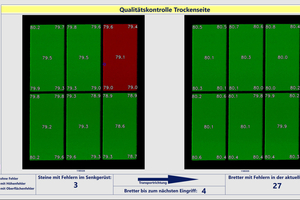

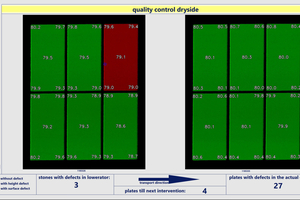

The more convenient the final inspection on the dry side is, the more efficiently it can be carried out. Manual sorting of individual defective blocks and pavers at the QA station is supported by a dedicated monitor. Thanks to the board ID, which seamlessly transfers quality data from the optical quality control on the wet side through the curing area to the dry side, staff at the QA station receive a real-time display of the products on the current production board.

Defective products are clearly color-coded and can be replaced manually in a targeted way. This contributes significantly to increasing the delivery quality of the finished product layers or complete pallets. Masa is already working towards an automated solution for quality sorting on the dry side and is developing various approaches with different levels of automation.

Work scheduling – more flexibility for staff

Masa has integrated an additional convenience feature for the personnel on the dry side: the ‘Lowerator preview’ function provides the operator with advance information on the production boards currently in the lowerator and being cycled step by step to the dry side.

Production boards requiring manual intervention are highlighted in color. The operator can also see how many defective products are in the lowerator and how many cycles remain until the next intervention.

This enables work to be planned and organized efficiently until the next necessary intervention—for example, emptying residual containers, carrying out cleaning tasks or refilling products for sorting.

As on the wet side, Masa also offers a configurable auto-stop function on the dry side. This ensures that no production board containing defective products enters the packaging process unnoticed.

Secure data storage and reliable support

Masa stores all data on-premises – directly within the customer‘s IT environment. The information is not stored in an external cloud but remains entirely within the company. This ensures that the customer retains full control over sensitive production and operating data at all times – a decisive advantage for concrete block and paver production, where reliability and data protection are paramount.

All services are supported by qualified specialists based in Germany. They have extensive experience and speak at least German and English, ensuring clear, professional communication – both nationally and internationally.

Masa provides a 24/7 technical support hotline. Based in Germany but accessible worldwide, it ensures customers receive rapid assistance at any time – regardless of location or time zone.

The combination of local data storage, technical expertise, bilingual support and constant availability ensures maximum security, stability and trust – allowing customers to focus entirely on production.

Creating new perspectives for tomorrow’s production

With optical quality control, Masa is opening up new perspectives for tomorrow‘s production. Marcel Helsper, Technical Director at Masa Andernach, describes the vision as follows: ‘Masa optical quality control is much more than a function – it is our ambitious step towards intelligent networking and increased efficiency in production, aligned with Industry 4.0.’

The focus is on analyzing production data to determine optimal parameters, supplemented by clear recommendations for operating personnel and intelligent assistance functions to support informed decisions. The aim is to increase production output over the long term and make processes future-proof.

Further research and development projects at Masa will drive this vision forward, signaling the next step towards smarter, networked manufacturing.

Facts, figures and data

1 mm²

0.5 mm

impurities

Integrated documentation

(defect detection, height measurement)