Curved bridge pylon marries artistic form with structural function

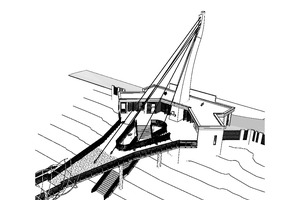

An eye-catching curved precast concrete pylon, designed by Orbic Architects and manufactured by precast concrete manufacturer, Superstruct, is the dominant feature of a new cable-stayed pedestrian bridge in Nelspruit, South Africa. Spanning 120m, the bridge will provide access to the new Mpumalanga International Fresh Produce Market, commissioned and funded by the Mpumalanga Economic Growth Agency (MEGA).

Completed in August 2022, the bridge was built to provide pedestrians with safe and unimpeded access across a car park to the main market hall. Using cable-stays, the 16.6m pylon supports a section of the bridge as a live load. The pylon rests on a cast-in-situ concrete column. Founded at ground level, it extends to an upper-level cantilevered platform which provides access to the bridge. The pylons were cast on-site in two massive precast sections. The lower unit weighed just under 40 tonnes and the upper portion 35 tonnes and in order to facilitate a trouble-free installation, the centre of gravity of both sections had to be calculated with great precision.

“We had to ensure that when they were lowered into position by a mobile crane, the flat top and bottom sides of both pylon sections were angled as per design for safe and easy installation,” said Superstruct managing director, Bruere Visser. “Our lifting designs were unique to each section and were complicated in that not only were both sections curved, but they were also tapered.What’s more, while the bottom section was completely hollow the top section was only partially so.“ The lower section was designed with 16 lifting inserts and the top section with 10. The inserts in both pylons were recessed and once each section was securely placed, the recesses were filled with a non-shrink grout.

Initially designed as a single in-situ installation by structural engineer, Pieter-Ben van Aswegen of Nemorango Consulting Engineers, the pylon was to have had rectangular bottom and top sections and rounded corners in the mid-section. „That configuration would have been uneconomic and complex to implement as a precast structure, so when we were invited to tender we proposed rectangular edges from top to bottom while maintaining the curved profile design. This modification was accepted by the professional team.“

Close collaboration between Nemorango, Peikko and

Superstruct

“The precast design involved casting the pylon in two sections. Had we done the casting as a single unit the cost of hiring a crane large enough to handle the weight could not have been justified,” said Visser. The pylon sections were secured in place using Peikko bolting systems, a process which involved close collaboration between Nemorango, Peikko and Superstruct. Besides supplying the anchor bolts and column shoes, Peikko coordinated the interface between the bolts and shoes and calculated the strength of bolting required for sheer and moment resistance.

Peikko’s anchor bolts were installed into the in-situ base column by Mgangatho Construction working as a sub-contractor and SMME partner to main contractor, Enzo Construction. Anchor bolts were also cast into the top of the bottom pylon. And 68 column shoes, which were attached to threaded rebar anchor bolts of between 1.1 and 1.4m, were cast into each pylon. “We also coordinated the interface between the anchor bolt and column shoe rebar and the rebar cage in both pylons,” said Daniel Petrov, managing director of Peikko South Africa. “Moreover, we ensured that the anchor bolts and column shoes were cast accurately using templates. This gave us a tolerance at the interface of 3mm or less,” explained Petrov.

The pylons were cast with polystyrene inserts to create weight-saving voids and a galvanised cable-stay base-plate was cast into the upper section. And once the top pylon had been installed, a 30mm thick cable stay anchor-plate plate was welded to the galvanised base plate. Cable stays were attached to the anchor plate during construction of the bridge deck which took place after the pylon had been installed.

Text: David Beer

CONTACT

Superstruct (PTY) Ltd

5th Ave, Bredell AH

Kempton Park, 1619/South Africa

+27 87 550 5287