Why even automate your production?

There are two questions arising when it comes to automation: Is it at all necessary to automate production processes of prestressed hollow-core slabs? And will there be no more people working in production if we automate?

First, we need to understand where we are today regarding the means of industrialization. It all began in 1760 with steam-powered mechanization, then evolved into mass production or so-called Industry 2.0 and went on to Industry 3.0, which was the first one with computers. We are now living in the Industry 4.0, data analytics and connectivity age and are entering the mass customization stage, i.e. Industry 5.0 – the era in which we will be working alongside machines.

Not only robots

Automation is so much more than robots substituting humans. Its main purpose is to reduce heavy and sometimes dangerous human labor in order to make the production process more efficient and safer, but – contrary to common belief – without wiping out the need for humans entirely. It is all about using specialized machinery and computers that can produce without needing human labor. Its goal is an intelligent production plant using data for an automated production process, where humans only manage the machinery and do not need to work on the product anymore.

Data- and machinery-driven production

Data needs to be transferred to the machines. Planning quality is much higher with automated machinery connected to the right software. Fewer human resources are needed, who are machine operators rather than heavy laborers. Given the shortage of skilled workers, especially for craft jobs, less human resources needed are a benefit. Also, manpower is one of the biggest costs, which must be kept low overall to stay competitive.

The right data usage results in less waste, and even errors can be reduced, which ultimately leads to fewer complaints and more satisfied customers. Efficiency will increase, as will product quality. This greater efficiency is achieved with up to 50% less manpower, making it possible to manage different stages of the production process with less manual work while avoiding extra working hours. The quality is better because automation improves consistency and reliability. With current prices and considering the ultimate goal of sustainable production, automation is the future. Automated machinery and software solutions are the efficient tools of modern production.

No automation without software

Data needs to be fed into the production process. Storage control, stack planning and productivity reports as well as design planning are the main focus of the software used in a precast plant. Stack planning is essential because the business needs to know the sequence in which products need to be delivered – and, consequently, in which order they must be manufactured. With the right software solutions, productivity reports can be implemented, which can help to analyze how to make the plant more intelligent, too. This is yet another benefit of detailed design planning using the latest software solutions.

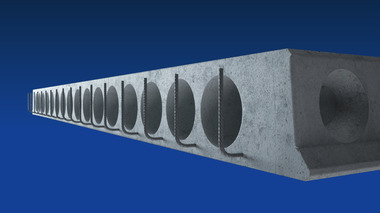

Automation in the production of prestressed hollow-core slabs

Enhanced machinery automation can also be achieved with a concrete delivery system with flying buckets and automatic ordering of concrete as well as the automatic discharge of concrete in the production machine. Thanks to the automated operation of equipment, the machine operator can work on other tasks while production is progressing.

Plotter tracing marks the positions of the cutouts on the slabs with extreme precision, down to the last millimeter, which is impossible to achieve by hand. The same machine also allows for drilling deep holes, while the actual openings still need to be inserted manually (for now).

Sawing of the cured slabs again takes place fully automatically, which makes the production flow safer, faster, and more accurate. This results in a cleaner factory, with fewer people on the shop floor who will work more safely and efficiently – thanks to automation.

The end result: less waste, fewer errors, a safer work environment – and higher quality within a shorter period of time.

CONTACT

Echo Precast Engineering NV

Industrieterrein Centrum Zuid 1533

3530 Houthalen/Belgium

+32 11 600 800