Innovative modular Reinforcement Assembly System

The company Skew Engineering, design house for reinforcement assembly products, provide fast and streamlined work methodology to the precast industry. Real life experiences through constant contact with the reinforcing steel bar industry resulted in the realisation of a unique reusable system for the assembly of rebar: Jiggelo. It is a modular Reinforcement Assembly System, which gives precast companies the means to up-grade manual production of reinforcement elements into an industrial process with machine-quality. The system catalyses a metamorphose in the operators, who evolve over time while using the Jiggelo. The operators quickly recognise and learn the best possible work method for assembly. This method on the Jiggelo is ergonomic and provides precise positioning with a constant high quality. Since its launch at the beginning of 2009, the modular Jiggelo system has been implemented with great success in 16 countries in a range of working environments. Being reusable, the system is eco-friendly and reduces the company’s carbon footprint.

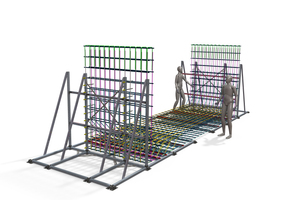

Jiggelo is the first genuine apparatus, made only for the assembly of rebar to ameliorate the steel fixer/welder work practice and deliver high quality elements for the fabrication of reinforced concrete products i.e. (ground-)beams, columns, box culverts, pile caps, staircases, (foundation-) cages and walls.

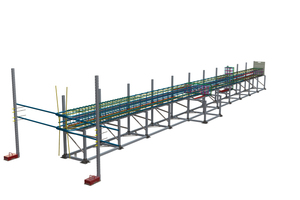

The Jiggelo modular concept consists of flexible multi-functional parts; reusable components that can be built into a multitude of model set-ups for specific purposes. Due to an innovative quick Connect Key System, existing models can be modified, rebuilt, extended or split into smaller models to suit the most effective assembly method for each new reinforcement element. The Connect Key System also facilitates the possibility to quickly dismantle the Jig model into stock parts, which gives flexibility to temporarily maximize the valuable production area for other purposes.

Constant high quality

(Production-) managers are able to organize various projects simultaneously, using static Jiggelo work stations, which are strategically set up. Alterations can be made within seconds, to meet the daily changes in assembly production for each project. Due to the self-explaining, quick erecting practice, large Jiggelo-models can be built within hours, not in days. Even the dreaded late revisions can still be made within minutes of receiving the information.

Once the system has been set up, loose rebar is assembled into high quality reinforcement elements with great ease and a reduced time span! Time and motion studies of the rebar assembly procedures before- and on Jiggelo, highlighted the reduced number of activities the operator makes while assembling rebar elements.

The system can be used for the most complex and unique reinforcement shapes that are difficult or not economical to be made with machines. The Jiggelo system provides a base for bespoke add-ons, improving the assembly procedure on an ergonomic and/or production efficiency level.

Pre-set lines, angles and distance holders contribute to the constant high quality of the reinforcement in concrete elements. By placing rebar onto a calibrated system, perfect position is assured. Innovative grips hold the reinforcement bars on the required plains at incremental 25 mm distances. The precision manufacturing of the Jiggelo assures perfect concrete cover for reinforced elements. High constant quality is required from products when reinforcement elements are to be assembled from combinations of sub-assemblies and standard mesh.

Production methology

The Jiggelo system provides an easy to learn structured work method. Compared to traditional assembly procedures, the system eliminates the unnecessary actions. By reducing the amount of actions for reinforcement assembly, the Jiggelo creates a natural streamlining in the procedure and a more transparent and lean production process. As the unique Jiggelo procedure consists of “loose positioning” in comparison to the traditional “fastened positioning”, it has generally been received as a revolution amongst the decision-makers more than once. Rebar is first positioned loose accurately before fastening.

Once all the element’s loose rebar is in position, fastening can be completed by any method of fastening.

Assembly of rebar elements can be different every day, bespoke and in small series. Standardization using a single work method appears to be not sufficient to handle all the daily challenges. Flexibility is the key to face constant changes in the daily production. Man is recognised as being flexible but it takes skill and time to deliver quality products constantly. Machines are setup for mass production and produce with constant quality. Yet machines are used for standardized output and therefore limited in flexibility. The answer is man combined with a tool that ensures constant high quality products, which enhances and increases work methods capability to machine standards, but also gives the flexibility that is often needed.

Aging work force

Around the world the number of proficient steel fixers is decreasing due to the 3D’s (Dirty, Dangerous and Demeaning) and a long learning curve. The unpopularity of the job amongst young workers has created a shortage of qualified ‘young blood’, a scarcity of knowledge is growing in the trade. This downward trend in the knowledge base calls for alternative systems, to enhance the strengths and prolong the activity of an aging steel fixer fraternity.

Jiggelo is the perfect system to increase the learning curve for new workers and to ease the working procedure in general.

An ergonomic and standardized production method makes work more pleasant and easier for the user. Reduction of stress and RSI makes the work safer, and more importantly, reduces injuries or accidents and therefore sick leave. Loose rebar being held by the Jiggelo, gives the steel fixer a hands free situation, implements a stress free working environment and allows the operator to fasten the material always in a good posture with ease. Additionally, the need to lift and/or hold heavy bars is reduced, because the Jiggelo platform has specially developed ergonomic add-ons for men to manipulate bars independently. The working height on the Jiggelo is variable. This prevents the steel fixer from working above their head or bending down, reducing the stretching beyond their physical limits.

The Jiggelo modular Reinforcement Assembly System enriches the reinforcing steel processing significantly for the precast industry. It guarantees high accuracy, flexibility and the enhancement and expansion of skills for the worker because of the fast learning curve. Moreover, the Jiggelo reduces actions during rebar assembly, preserves the worker and provides unlimited possibilities of set-ups for specific rebar elements.

CONTACT

Skew Accessories B.V.

Empermolen 10

7399 AP Empe/The Netherlands

+31 575 501154

CONTACT:

SKEW Accessories B.V.

Zonnenbergstraat 34

7384 DL Wilp/The Netherlands

+31 571 260115