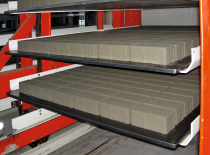

UPplus production boards at Bauma 2016

After the acquisition of the production board division from Rettenmeier Holzindustrie, MyWood has continued to operate this business under the brand name UPplus with success for two years now. With a workforce of about 200 people MyWood is manufacturing at their Polomka location in Slovakia products of softwood, including the said UPplus production boards for manufacturers of concrete blocks all over the world. Furthermore, the product range of MyWood comprises P20 formwork beams, 3-ply shuttering panels, 3-ply natural wood panels and wood pellets.

We are still manufacturing according to the well-proven Rettenmeier technology, namely with dovetail joint and waterproof polyurethane glue, and committed and skilled employees. The big advantage of the production site in Polomka that is to be expressed is the good access to high-quality raw materials. The wood with very small annual rings provides for excellent density values, resulting in a final product with better vibration transfer and less abrasion. “This is a significant competitive advantage”, says the German production manager Josef Beer.

A professional sales team and competent agents in all important foreign markets are further factors for success. “Since the acquisition, we have sold our production boards to more than 60 countries in two years,” says Sales Manager Tobias Schmidt.

In 2016, MyWood aims at growing in the division of production boards of softwood. In April, the MyWood team will present itself and the entire product portfolio at Bauma in Munich in hall 2 A, stand 231.