The BT turnbuckle – a durable and versatile connection

The BT turnbuckle is used and applied in many different industrial sectors. This easy to handle connection system is used for robust and precise erection works and for durable connection of precast concrete elements. With this innovative turnbuckle and suitable connections, precast concrete elements can be connected to each other without mineral casting compounds. Erection takes place entirely independently of the weather and can be easily implemented even in minus temperatures or in rainy weather.

The advantage of the BT turnbuckle is easy to see – on construction sites, it eliminates complex curing and downtimes due, for example, to low temperatures. Customers can profit from this in terms of savings in time and costs. In addition, connections established with the BT turnbuckle can be fully loaded immediately following installation.

The BT turnbuckle is, moreover, demountable and dismantling of already erected structures is possible as well. This versatile and innovative solution has also convinced the supervisory bodies. Approval by the construction authority (Z-14.4-599) certifies the reliability of this product.

The BT turnbuckle is used in many industrial sectors

The turnbuckle can be universally and reliably used for the most diverse applications: among others, in erection of angular supports and manhole elements in road and underground construction, structures in the maritime sector and coastal protection, floor and wall connections in residential buildings and the comprehensive range of precast concrete elements.

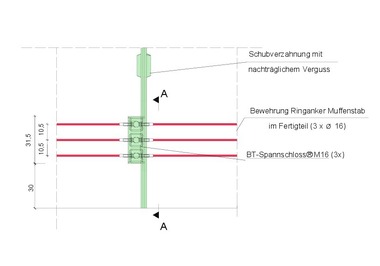

Customers are offered the BT turnbuckle in three sizes – M12, M16 and M20 – in each case of galvanized or stainless-steel design. A suitable blockout unit is available for all three sizes. The standard version of this component consists of polyethylene and features inclined sides for easier demolding. The blockout units are especially robust and can be used many times.

The blockout units can be fitted with magnets for still faster und even more reliable application. For use with wooden formwork, they can be screwed or drilled in place. On request, the dimension or shape of the units can also be individually adapted, thus offering a made-to-measure solution for every connection.

Rapid construction of a hotel with comfortable turnbuckle solutions

The BT turnbuckle has already been used in many prestigious construction projects. One flagship project is the newbuild Hilton Garden Inn Hotel in London, situated directly adjacent to Terminal 2 of Heathrow Airport. The building is 15 stories high and has an overall height of 47.60 m.

The challenging requirements of this project were due primarily to the sensitive location in the protected security area of the airport and a very short construction time of just 30 weeks for erection of the precast concrete elements. The building contractor commissioned with the construction decided on the BT turnbuckle for fast and reliable erection.

For each of the external wall units, four M20 BT turnbuckles were used. In this way, propping of the external walls was no longer required and the walls were secure immediately following positioning. The advantages of the BT turnbuckle were obvious – the erection time was significantly reduced.

Connection solutions in underground construction and energy generation

The BT turnbuckle is also used in flood protection. The need for appropriate measures has gained new importance – at the latest, since the catastrophic floodings of the past 20 years. This generally involves much time for planning and construction, resources and costs. A simple and highly effective method for erection of protection walls are angular supports of reinforced concrete with the BT turnbuckle.

The principle is simple – the angular supports are placed on a suitable and prepared foundation. In unfavorable soil conditions, an additional, deeper anchoring is possible. The RubberElast sealing tape is applied to the lateral edges of the concrete elements. The tape is easy to attach and, due to the contact pressure applied, the joint is sealed waterproof. For this, the BT turnbuckles are tightened and the sealing tape squeezed until the necessary joint width is achieved. From this point of time, watertightness is achieved and the system can immediately be fully loaded. Especially during flood events, when protective walls must be erected within a relatively short time, the turnbuckle is a guarantee for fast, simple and reliable implementation.

This solution was implemented in 2014 for two projects in the popular seaside resort of Heiligenhafen in Schleswig-Holstein in Northern Germany. To do justice to the optical demands of the idyllic environment of this tourist stronghold, color pigments were added to the concrete for one project, thus coloring it suitably to harmonize with the surroundings, The result is a technically reliable and at the same time optically appealing solution.

The BT turnbuckle has also found its place in the ecological sector. In Jemgum (in Ostfriesland) in Northern Germany, a biogas plant of over 75 kW was commissioned. For this project, the BT turnbuckle was used for connecting precast elements. This enabled rapid construction within a short erection time of only 20 minutes per element. In this way, the erection time of the originally scheduled three days was reduced to just one day. The turnbuckle met the strict structural requirements without problem, and the entire plant could be put into operation already two months later.

Another example for use of the BT turnbuckle is the newbuild of a pipe shaft in Zielitz (in the German State of Saxony-Anhalt). This pipe shaft serves for extension of a spoil heap and for securing extraction of potash. Here, too, the professional connection solutions of B.T. Innovation GmbH facilitates many work steps and results in tremendous time savings.