Success story: Yongfeng Bürkle revolutionizes the market for precast elements in China

Based in the town of Sasbach in Baden, the Bürkle Group has been a producer of concrete elements for over 60 years – including wall and slab elements as well as customized precast elements such as staircases, columns and balcony elements. The Chinese Yongfeng business group took over the Bürkle Group at the beginning of 2019, resulting in a win-win-situation for both parties.

Based in the town of Sasbach in Baden, the Bürkle Group has been producing concrete elements for over 60 years – including wall and slab elements as well as customized precast elements such as staircases, columns and balcony elements. The family business was founded in 1957 and comprises building materials supplier Walther Bürkle GmbH & Co. KG, concrete producer Bürkle GmbH & Co. KG, Bürkle Kellerbau GmbH & Co. KG, and the Swiss company Bürkle Kellerbau GmbH.

With a current annual production of an estimated 150,000 m² of double walls and 180,000 m² of slabs, as well as in excess of 500 completed basement projects, the Bürkle Group is one of the top performers in this sector nationwide. The construction elements produced equate to an impressive area of almost 2,500 tennis courts – per year.

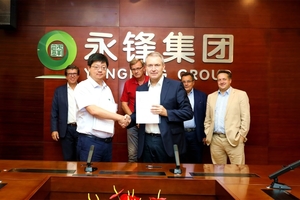

A German-Chinese story of success

Managing Director Johannes Bürkle is a man of vision and is always on the lookout for new opportunities for development for the entire company. That is why the question of succession was a priority for him even at an early stage. The solution finally presented itself in the form of a partnership with the Chinese Yongfeng business group. Yongfeng took over the Bürkle Group at the beginning of 2019, with Johannes Bürkle continuing to act as Managing Director. The international acquisition was coordinated by Thorsten Zegrotzki, chairman of the Advisory Board of the Bürkle Group and adviser to Yongfeng. This “feat” turned out to be a real win-win situation for both parties.

The Chinese business group is based in Qihe near Jinan, capital city of the province of Shandong. It produces steel and iron ore and is also active in the building and real estate sector. Other business areas include education, municipal services, retail, logistics and financial investments. Yongfeng is among the top 500 Chinese companies and employs a total staff of around 11,000. With the Bürkle Group as proven experts, Yongfeng is planning substantial investments in the precast concrete sector of the Chinese market and is setting impressive goals: the plans provide for ten new plants – the first currently being built in Dezhou, 90 kilometers from the Group’s headquarters. The circulation system for slab elements has already been put into operation whilst the second is still under construction. For this start-up, Yongfeng is still looking for an experienced plant manager to coordinate the local team and lead it to achieving the anticipated productivity – certainly one of the most exciting positions in the precast industry at present (see job advertisement on page 71).

Johannes Bürkle – designer and visionary mind

Following a thorough selection process by the Bürkle Group, the leading supplier of end-to-end solutions for the precast concrete industry – the Progress Group – was chosen to provide the equipment for the new plant. The circulation technology was supplied by Ebawe Anlagentechnik, the reinforcement machines by Progress Maschinen & Automation, the software by Progress Software Development, all member companies of the Progress corporate group. The designer – and therefore visionary mind – of the new precast concrete plant is Johannes Bürkle, who contributed his more than 30 years of experience and designed the perfect plant.

The new plant of Yongfeng Bürkle Construction Technology Co. Ltd. comprises two circulation systems: one for the production of precast slabs, the other for massive and sandwich walls with integrated reinforcement section and a second level for manual shuttering and deshuttering of the pallets. These are lifted to the upper level and then lowered again by means of a transverse transport system including lifting feature. The circulation system for the production of precast slabs comprises 70 pallets, two plotters, one concrete spreader, two compaction units, two roughening units, one storage and retrieval unit for storing and retrieving the concrete elements in a curing rack, one crossbeam for lifting the completed slabs, as well as units for cleaning and applying a release agent to the pallets.

The circulation system for massive walls and sandwich walls with integrated insulation is equipped with 35 pallets, a floor-operated lifting transfer table, concrete spreader and compaction unit, as well as a vibrating leveling screed for leveling and subsequent smoothing of the fresh concrete surface. The external vibrators attached to the screed effect additional compaction in accordance with the concrete layer depth. Pre-smoothing and fine-smoothing of the concrete surface is effected by means of a troweling machine. The recently installed flying bucket line was supplied by Kübat Förderanlagen; the mixing plant was supplied by a Chinese manufacturer.

Further precast concrete plants to be built in China

As regards reinforcement, the plant is equipped with a new M-System BlueMesh mesh welding system from Progress Maschinen & Automation with an integrated bending machine suitable for bending the beams on both sides, thus significantly reducing time and labor requirements. Additional plant components include an MSR straightening, cutting and bending machine with automatic straightening rate adjustment, as well as an EBA S 16 automatic stirrup bending machine with anti-twist system and automatic straightening roller adjustment. The VGA Flex lattice girder welding machine with fully automated height adjustment provides for a high-quality and cost-optimized process flow in the supply of reinforcement elements.

The circulation systems are controlled and monitored via the Ebos process control system supplied by Progress Software Development. The Stabos software system – also created by Progress Software Development – is available to the customer for the collection and analysis of production data.

The new plant will advance building with precast concrete elements in China – especially in housing construction. In addition, the factory is intended to serve as a reference plant with integrated visitor platforms and extra walkways for interested parties. Since the coordination processes and construction of the first plant went exceedingly well, it is not surprising that Yongfeng Bürkle and the Progress Group are seeking to continue their business partnership: discussions are already underway with regard to additional precast concrete plants in China.