Opus Fluidum Futurum – Report from the DFG Priority Program 2005

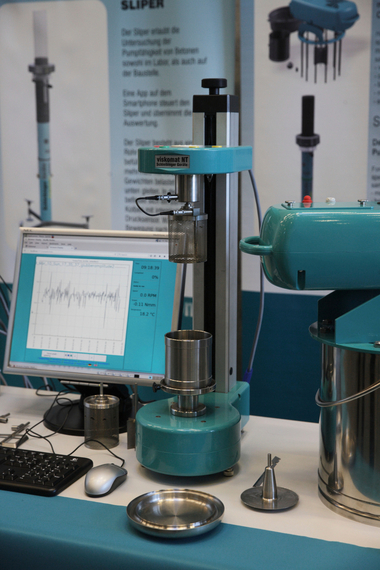

The processing of cement-based building materials is at the technological core in the construction and maintenance of structures. Although formability in the fresh state offers almost unlimited possibilities for shaping structures and developing new construction techniques, today only a tiny fraction of this enormous potential is used. The lack of a scientific framework for mastering rheology-based processes is a major obstacle to developing novel and highly innovative construction technologies, such as 3D printing with concrete (Fig. 1), as well as to solving current technical challenges, such as pumping to extreme heights.

The reason behind the shortcomings of the rheological framework is the extremely high complexity of the cementitious systems. Only seconds after the addition of water, the high chemical reactivity of mineral binders leads to changes in the particle morphology, the dissolution of larger and formation of new nanoscale particles, and severe alteration of the carrier liquid chemistry. Both the newly formed nanoparticles and the carrier liquid interact, in turn, with granular raw materials up to several centimeters in size (multiscale). In addition, cementitious suspensions are always complex multi-phase systems that contain organic admixtures and air voids in addition to water and various mineral particles. Finally, cementitious materials are cast and processed under an enormous range of deformation rates, which result in extremely high demands for characterization and simulation methods.

Objectives of the Priority Program

The goal of the Priority Program “Opus Fluidum Futurum – Rheology of reactive, multiscale, multiphase construction materials” (SPP 2005) is to ascertain and describe the scientific fundamentals for understanding and subsequently designing rheology-based construction processes as well as for developing innovative, sustainable building materials and associated pioneering processing technologies. The program includes the entire scientific spectrum related to the rheology of cement-based materials before hardening.

The main scientific objectives of the program are:

To investigate and analyze the interactions of reactive (hydrating) particles on the microscale, including the quantification of influences (morphology, chemistry, temperature, time, etc.) and the modeling of particle interactions

To develop strategies and concepts for the description of deformation and flow processes of fresh concrete based on microscale processes and taking into account mesoscopic processes (segregation, deaeration, fiber distribution, etc.)

To analyze and comprehend the relevant processing operations of fresh concrete (transport, casting, compaction, finishing, etc.) using scientific tools and methods of rheology

To elaborate measurement methods for the detection of the fresh concrete behavior at different levels of consideration and various claim scenarios

To develop constitutive material relationships for fresh concrete to simulate the phases and actions of processing

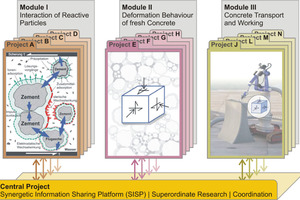

To achieve these objectives, the program

is divided into three

modules, see also Fig. 2.

Module I: Particle interactions as the basis for the rheology of binder suspensions

Module II: Flow and deformation behavior of fresh concrete

Module III: Constitutive relationships and methods for describing and influencing technological processes

When selecting the processes considered, priority is given to the rheological behavior of the ready suspension, rather than to the technique for producing this suspension. The rheological properties of the suspension are also in the focus of research at the interface between concrete technology and machinery. The purpose of the program is, however, not to optimize/improve individual technological processes, which should occur in the framework of subsequent research projects.

Implementation of the Priority Program

The entire duration of the program is six years; the total funding volume will be approximately 15 million Euro. The program includes 17 individual and joint projects as well as a coordination project. Most individual projects started at the beginning of 2018. Scientists at 17 universities and research institutions participate in the Priority Program. The coordinator of the SPP 2005 is the first author of this article, while the second author is its manager.

The synergetic research in the SPP 2005 has started with the choice of reference mixtures and substances, reference methods, standard procedures, and file formats of communication to facilitate the comparability of the observed results from among all the individual projects and to generate the synergetic exchange of relevant scientific information. The so-called Synergetic Information Sharing Platform supports this collaborative research, see Fig. 2. At the core of this platform is a joint database run by the coordination project. Three working groups have been established to bring forward particular activities in a synergetic manner:

1) Material characterization

2) Rheometry

3) Numerics

The joint research is made possible by a variety of activities such as round-robin tests, workshops, summer schools, etc. Top international and national scientists from recognized universities, research institutes and the industry have been invited as speakers and experts to bring the priority program to international vibrancy. The first results of the SPP 2005 were successfully presented in a special session at the tandem conference in Dresden held from 9 to 11 September 2019: the 2nd International Conference on Rheology and Processing of Construction Materials and the 9th International RILEM Symposium on Self-Compacting Concrete [1].