On obtaining a general building approval (abZ) for car park ceiling slabs with carbon concrete

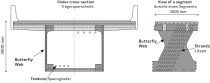

Carbon concrete is a recent material for which carbon-fiber strands as a composite material in the form of non-metallic reinforcement are inserted in concrete and for which no long-term experience is available yet. Therefore, a profile of requirements has to be determined for the use of carbon concrete in floor slabs for parking garages; this basically includes the temperature at the level of the reinforcement layer, the intended service life, a long-term load to be expected, as well as a potential impact of the alkaline environment and possibly existing moisture in the structural component. In addition, a dynamic loading that is not stipulated as standard requirement but can quite adversely affect the bond between concrete and reinforcement. This results in an experimental concept which, in comparison to current application areas of carbon concrete (reinforcing, repairing and strengthening), moreover does not use a high-performance fine concrete, but a normal-strength concrete with a large grain of 16 mm.

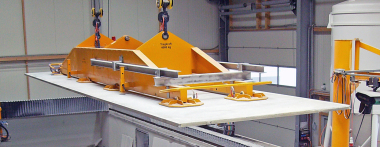

An experimental concept was derived from this profile of requirements and is focusing on a so-called durability test with overlapping of the maximum possible boundary conditions. That is to say, a long-term load in at least the range of short-term strength being determined previously in an aqueous solution with a pH value of 13.7 and a test temperature being 15 K below the glass transition temperature of the impregnation material of the reinforcement. In this way, in a time-lapse testing and by means of an Arrhenius equation, it is possible to determine the strength at the time of the intended service life. Structural components in full scale, moreover, provided design values on the resistance side. A systematically structured test concept that was successfully completed and a quality assurance concept provided for the basis of a national technical approval of floor slabs for parking garages made of carbon concrete.