Non-destructive testing simulating a tunnel fire

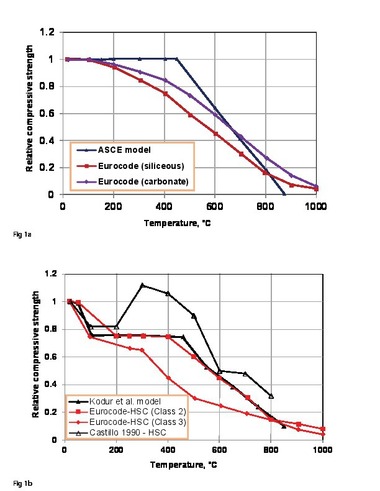

In the event of a tunnel fire, there is hardly any possibility for the heat to escape, leading to a temperature increase to over 1,000 0C within an extremely short period. Consequently, water vapor forms inside the concrete, and the built-up pressure first expands into the voids present in the material. Above a certain threshold, however, small pieces of concrete will detach and reduce the thickness, and thus structural capacity, of the concrete.

Voids created by molten fibers

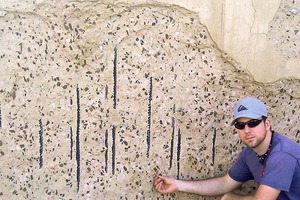

Since 2012, new road tunnel projects have been subject to fire safety verification prior to construction. One of the options to ensure fire protection is to add polypropylene (PP) fibers to the concrete. “Once the temperature exceeds 110 0C, the fibers start to melt within the concrete,” explains Prof. Christian Große, of the Chair of Non-Destructive Testing at Munich University of Technology (TUM). This addition of fibers results in the formation of new voids in the concrete into which the pressure can escape. Previously, it had not been understood how plastic fibers influence the behavior of concrete in the event of fire.

During tests at TUM, researchers placed concrete slabs on an open test kiln and installed sound emission sensors on the top side of the slab. The concrete was exposed to fire from the kiln underneath and heated to 1,300 0C. “A certain type of cracking sound occurs when the concrete is damaged,” explains Ronald Richter, PhD candidate at the Chair of Non-Destructive Testing. The associated acoustic wave is transmitted within the material and can be measured on its outside. Since several sensors are fixed to the concrete slab, it is possible to determine the exact location of the source of this sound, similar to the monitoring of earthquakes using seismometers.

For the first time, engineers were able to measure the development of concrete damage over time during a simulated tunnel fire. Compared to concrete slabs with PP fibers, sound emission events occurred more than ten times more frequently in slabs without such fibers.

AiF project funded by Federal Ministry

The researchers intend to further refine and validate their measuring method, which could help to compare the fire behavior of various concrete mixes and to optimize them.

This research was conducted as part of the DFG (German Research Foundation) project on “Explosive Spalling of Concrete Under Fire” jointly with the Institute of Construction Materials at the University of Stuttgart, as well as in an AiF project funded by the Federal Ministry for Economic Affairs and Technology in cooperation with the Leipzig Institute for Materials Research and Testing (MFPA Leipzig).