Mesh welding lines for the precast and construction industries

Eurobend offers one of the most comprehensive range of mesh welding lines for the production of any type of mesh used in precast operations and in the construction sector in general.

In addition to the broad range of welding lines supplied for the production of standard and specialized construction mesh, engineering, precast or architectural mesh, Eurobend GmbH provides a full range of automatic welding machines for producing all types of mesh and bar spacers/supports, girders and similar products.

For the production of the different types of bar supports and spacers, Eurobend GmbH offers the machine types referred to below, which are servo-driven and provide the following features: multiple cross-wire feeding for increased production rates; minimal changeover requirements; fast and accurate diameter changeovers due to quick set-up straightening systems, covering a broad range of wire diameters without extra tooling requirements; unique bending system ensures excellent repeatability; line wire convergence guide system for automatic product height changes in less than 2 min; user-friendly software requiring no programming skills; fully automatic, synchronized stacking and batch removal process. An operator is only required to supervise the production proc-ess and remove the automatically produced spacers.

Welding machines

for reinforcement cages

and mesh

The PLT & PLR B Spacer Series is a fully automatic bar support machine that provides highest production speed (one complete product in less than 4 s) whilst also featuring fast and accurate product changeovers; it is available with either T type or overlap welding heads, depending on the required welding style between the cross and runner/line wires.

PLR BB Spacer Series: All types of plain-bar supports can be produced by the same machine, in less than 4 s (six cross-wire machine version), and its highly efficient two-stage bending operation provides excellent accuracy and repeatability.

On the first stage, which employs two multiline bending stations (one per each side), all cross-wire ends are bent at once. On the second stage, the mesh is formed into the required bar support. The final product is discharged on an inclined table for easier collection and stacking.

PLR CFB Spacer Series: All types of plastic-cup bar supports can be produced by the same machine; its patented wire-stamping/notching mechanism and expansion of plastic cups guarantees elimination of loose plastic cups, and the unique mechanism for rotation of plastic cups always ensures feed of the plastic cup on the correct side.

The PLT B Ladder Series of welding lines ensure simple machine layout, reliable and cost-effective production of ladder-type strip spacers from coils. Line and cross wires are fed directly from coils through a compact straightening and multi-roller servo-motor driven feeding unit. The machine can be supplied with T type or overlap R type welding heads. The unique, patented bending system ensures excellent repeatability. Up to five synchronized, pneumatically operated bending units form the strip spacer during ladder production. The line-wire convergence guide system ensures automatic product height changes in less than 2 min. Programmable line-wire feed allows variable cross-wire spacings within one and the same spacer and automatic stacking of strip spacers during production flow. An operator is only required to supervise the production process and to remove the automatically produced strip spacers.

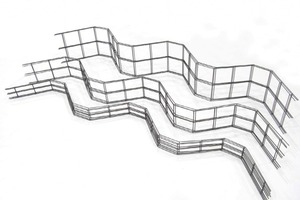

The PLT & PLR Truss-Single Girder Series welding lines ensure simple machine layout, reliable and cost-effective production of truss and single girder production. The machine can be supplied with T type or overlap R type welding heads. The fully programmable servo-driven diagonal wire-bending device ensures excellent accuracy, repeatability and fast size changeovers. Powered de-coiling stations for line and diagonal wires with tension detector ensure smooth wire feed. The straightening section employs roller-straightening equipment with patented product leveling, anti-twist rollers. The special wire guiding system with multiple moving gripping points guarantees high output quality. This series guarantee automatic stacking of meshes during production flow.

Fully automatic lines

for lattice girders

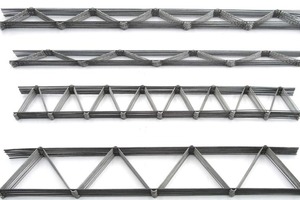

The PL-Tris Series of lattice-girder welding lines can produce most types and sizes of lattice girders and offer reliable and cost-effective production. Different models are available for both the economic and high-output production of lattice girders. Powered de-coiling stations for line and diagonal wires with tension detector, or wire loop accumulators depending on the type of machine, ensure smooth and accurate wire feed. The straightening section employs roller-straightening equipment with patented product leveling, anti-twist rollers.

The special continuous bending system designed for double and quad step lines uses retractable bending pins for the two diagonal wires and ensures accurate and consistent operation. Flexible welding heads provide electrically driven height adjustment for producing lattice girders in various sizes. The system includes hydraulic clamping units mounted on a servo-driven carrier; it ensures accurate wire feed and lattice girder production. Its high-speed cutting operation enables continuous lattice girder production. Semi- and fully automatic, synchronized stacking and batch removal modules are available.