Keller IMS - solutions for industrial production processes

Keller, a traditional company from Ibbenbüren-Laggenbeck, looks back on a history of more than 125 years. The aspiration of Keller has always been to develop high-quality machines and plants for its customers on the basis of innovative technologies. This guiding principle, manifested in the corporate slogan “Creating Solutions”, is also the focus and driving force for the Keller IMS division.

With the experience and a feeling for what is feasible, the qualified employees develop and design highly flexible machine and robot supported concepts optimally adapted to the product. When standard solutions reach their limits, whether for performance, flexibility or space reasons, we are in demand.

Where previously the material was transferred by machine solutions with rigid processes, we achieve higher efficiency and productivity of the production line through highly automated machine concepts and intelligent control systems.

It is important for us to enter into a constant dialogue with our customers from the beginning in order to fully understand and analyse the handling processes, the automation and machine solutions as well as the upstream and downstream process steps.

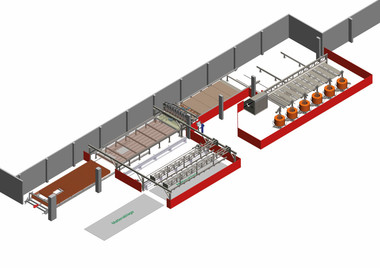

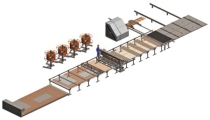

Machine and automation solutions for industrial production processes

As a manufacturer of overall solutions from machine technology, control and automation technology to process visualisation - all from one source - the modules are optimally matched to each other and offer a high degree of flexibility. Thus, solutions from Keller IMS can be easily and individually integrated into existing production lines. Through possible 3D simulations and virtualisation, the solution becomes visible even before the start of production in order to take into account any room-specific particularities. The aim is to achieve maximum plant availability through a plant concept optimally developed for the manufacturing product, through the durability of our machines, through short set-up times and low maintenance work.

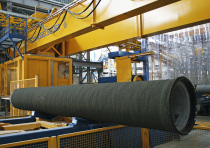

Gripping as well as the lifting and lowering process is decisive for the safe handling of materials. Sophisticated gripper and take-up systems form the basis for the most different types, dimensions and weights of material handling with minimum space requirements. Thanks to a very extensive portfolio of gripping devices, the machine solutions can safely pick up and set down the most different products, such as glass pipes, paint buckets, porous concrete and sand-lime bricks up to concrete channels. Keller grippers are not only limited to opening and closing, but also turn, spread and group the products during handling. In this way, a part of the previously additionally required plants and machines are replaced by our machine solution. The range of services is completed by measures and facilities to ensure the safety of production processes, such as the performance of safety audits.

Today, modern handling and palletising technology networks the internal material flow with high production speeds and high precision thanks to positioning and collision control systems. Keller IMS does not only develop the machines for this purpose - we develop complete solutions for your material handling with the ambition of maximum possible efficiency.

Today, plants and machinery built by Keller run around the clock all over the world. Keller machine technology has proven itself especially in rough and demanding environmental conditions, such as in building material production plants. The company supports innovations and new developments and takes environmental protection into account in all its activities. Keller ensures that the high requirements they set for themselves and which the customers address to Keller, will be optimally fulfilled.

CONTACT

Keller HCW GmbH

Intelligent Machinery Solutions IMS

Carl-Keller-Str. 2-10

49479 Ibbenbüren/Germany

+49 5451 850