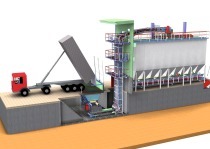

Innovation: The VHV FlatFeeder

The VHV FlatFeeder offers numerous advantages, according to the manufacturer, as an alternative to underground hoppers or complex unloading units based on chain conveyors. The unloading unit can be fed by truck, wheel loader, excavator or crane and is based on the innovative VHV belt conveying technology. When loading by truck, the entire load can be picked up even when the take-off conveyor is stationary. To do so, the truck enters the feeder up to the front wedge and dumps the load onto the partially accessible slatted grate.

Just as in tipping operations on normal ground, the trucks empty completely when pulled forward. The attached hopper permits convenient access and is designed so as to avoid damage to the truck tires. The trucks are unloaded quickly, enabling the semitrailers to drive away again after only a short period of time.

The VHV FlatFeeder has a buffer volume of about 22 m³, and the material is discharged at an adjustable conveying rate ranging from 40 m³/h to over 400 m³/h. This enables the output to be adjusted to the subsequent process step. The height offset is only 1,500 mm due to a recess or ramp.

When the hopper is emptied, material residues are loosened and discharged effectively by means of short vibration pulses. This ensures separate feeding of materials according to type and low noise emissions.

Since the VHV FlatFeeder does not require a basement, there is no need for extensive earthmoving operations and concreting work. The machine is pre-assembled prior to delivery and is of portable design, which permits rapid assembly. Although a stationary unloading conveyor, it can be relocated in accordance with requirements. The VHV FlatFeeder is also ideally suited for use in combination with the company’s steep-incline conveying technology.

CONTACT

VHV Anlagenbau GmbH

Dornierstr. 9

48477 Hörstel/Germany

+49 5459 9338-0