Influence of fiber orientation on the mechanical properties of ultra-high performance fiber-reinforced concrete

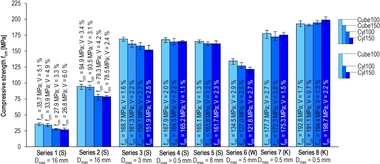

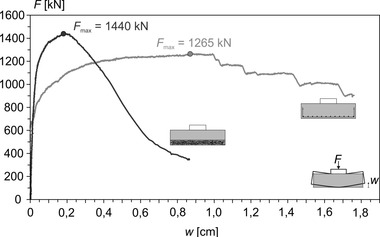

With steel fiber reinforced concrete, not only the fiber volume fraction, but also the fiber orientation has a decisive influence on the mechanical properties. This is especially true for the behavior under tension. Here, the axial post-cracking tensile strength significantly depends on the orientation of the fibers in relation to the tensile direction. However, the fiber orientation is also important with regard to the compressive strength and the post-fracture behavior of the concrete, since the fibers decelerate the growth of microcracks parallel to the compressive direction and bridge macrocracks after the fracture has occurred.

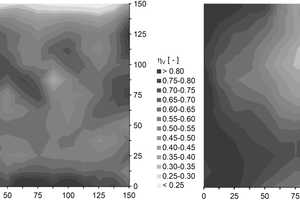

In general, the orientation of a fiber is characterized by the so-called fiber orientation coefficient. This corresponds to the cosine of the angle between the longitudinal direction of the fiber and the direction orthogonal to the cross-sectional plane under consideration. The fiber orientation coefficient can reach values between 0 (orientation of the fiber in the cross-sectional plane) and 1 (orientation of the fiber normal to the cross-sectional plane). The evaluation of the fiber orientation can be carried out with different methods, which either explicitly provide the fiber orientation coefficient or only predict the mean proportional orientation of the fibers in the three spatial directions or the preferred direction of the fibers.

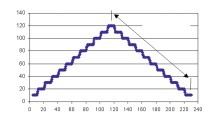

Since the fibers are preferably aligned in the flow direction of the fresh concrete and parallel to formwork surfaces, the fiber orientation essentially depends on the geometry of the test specimen or structural member, the fresh concrete consistency and the pouring technique. In this way, very different fiber orientations can locally occur within a concrete volume. The fiber-reinforced concrete then no longer behaves isotropically, but shows different tensile and compressive behavior depending on the direction of loading. The anisotropy is more pronounced with increasing fiber volume fraction. This aspect is of particular relevance for ultra-high performance fiber-reinforced concrete (UHPFRC), as UHPFRC is usually applied with high fiber volume fraction.