Influence of Additives and Admixtures on the Thixotropic Properties of Pastes

A conventional SCC with very flowable consistency is not suitable for use in the slipform paving process, which is why a concrete with pronounced thixotropic characteristics must be used for this purpose. The research reported on in this article evaluated cement pastes that were to be used for the production of thixotropic self-compacting concretes. The relevant characteristics of the pastes include a high flowability and a markedly thixotropic behavior or a high dimensional stability of the free-standing element within a very short period after casting.

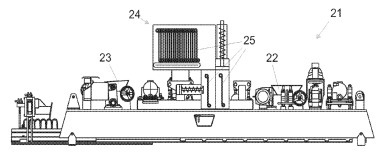

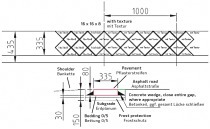

To date, low- or no-slump concretes have been used for placement in the slipform paving process to create concrete road pavements. It is thus imperative to compact the concrete using internal vibrators that are firmly attached to the slipform paver. This process will often lead to an elevated fine mortar proportion in the vibrator paths, which may modify the properties of the concrete compared to theareas outside these paths.

These weaker zones result from the system used, and cracks may occur in these areas in the course of the use of the pavement. The vibrator paths are not necessarily the cause of the cracks but determine their locations [1]. The use of self-compacting concrete may facilitate the placement of concrete for slip-form paving whilst improving it commercial viability and eliminating the vibrator paths that had been identified as potentially weak areas above.

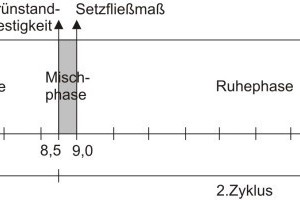

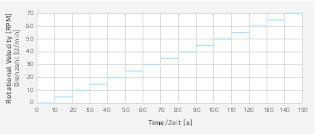

For this purpose, however, the concrete must have a high green strength in addition to its highly flowable and selfventilating properties already after a few minutes, i.e. after discharge from the slipform paver, in order for the pavement slab to retain its shape in fresh condition. Thus, a highly thixotropic fresh concrete needs to be developed. In the initial phase of a research project designed to develop such self-compacting concretes with high green strengths, cement pastes were used to identify the key parameters with an influence on the flow behavior and thixotropy of concrete. For this purpose, varied material mixes were used in terms of concrete admixtures (e.g. thixotroping agent, plasticizer and sheet silicates) and additives (e.g. quartz powder and metakaolin).