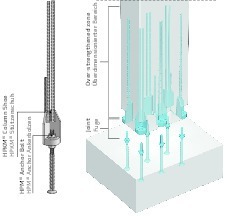

Highly efficient force transmission between precast

HPC sections

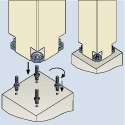

This new type of connection adds another option to the range of possible connections in precast reinforced concrete construction. Columns can be produced without interrupting the standard formwork due to the custom panel form. Columns can be placed more easily on the truck allowing for efficient transport because the components are joined on the construction site. This technique is also suitable for producing other connections in building construction, such as beam-to-column or modular truss joints.

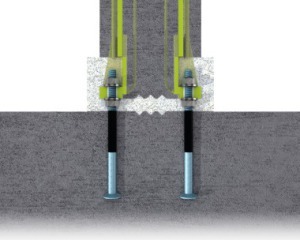

Function

The new connection comprises two toothed steel components, with each of them being cast...