Gothic style replicated in concrete – Cadogan Song School, Perth

A Choir Song School composed of precast elements was added to the Anglican Cathedral in Perth, Australia. The canopy-like roof of the building was designed as a shell structure, replicating Gothic style and blending in harmoniously with the heritage site.

At first glance, the new building appears to resemble a chapel set in front of the south-eastern chancel façade of the Anglican Cathedral in Perth, Western Australia. Yet this addition accommodates the new Song School named after its sponsor, wealthy British aristocrat Charles Cadogan, who is also a member of one of Britain’s most prominent real estate dynasties. While the cathedral is a late 19th century neoclassical brick building, the strikingly white surfaces and reduced shapes of the new addition make it a true contemporary building that, however, consciously replicates Gothic aspects as it features 14 ribbed vaults in a paired arrangement that form a canopy-like roof structure covering an area of nearly 100 m² whose western half extends over a subterranean single-story choir rehearsal hall. Its eastern half comprises a staircase spiraling up around a slightly accentuated central axis. This upper portion basically functions as the roof of the rehearsal hall located at the level of the cathedral, which was built on a natural terrace within the cityscape. The choir rehearsal hall is effectively located in the corresponding lower story, whereas its ancillary rooms are dug into the ground, reaching up to the cathedral foundations. The new building was designed by Perth-based Palassis Architects, who look back to a history of many other projects previously completed for the Anglican diocese. Pact Construction, an engineering office also based in Perth, took care of the structural design of the building.

Vaults designed as a precast shell

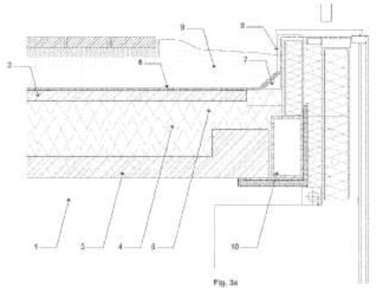

All visible components of the Song School consist of precast white concrete elements with a slightly textured surface. They include not only the three grid-like wall units, the vaulted ceiling beams of the rehearsal hall and the roof cross supports, but also the ribbed vaults of the roof bays and the two spires of the central tower extending above the spiral stairwell. Each of the roof bays is composed of four precast elements that make contact with each other at the vaulting apexes. The precast components extend over the entire height of the completely open upper story and appear, somewhat surprisingly, as a monolithic structure to the observer, who will identify the apex joints only at second glance. Most of these semi-domed elements directly connect to the dark grey natural stone flooring laid on the upper level, which eliminated the need for providing a horizontal joint near the floor. However, a separating joint had to be inserted on the outside where the vaulted shells sit directly on the cross supports of the ground floor, forming a vertical line in combination with them. To round off the monolithic appearance, the architects specified concealed hinges and connections for all precast elements, which was ensured by steel bolts embedded in the concrete that were inserted into the cross supports and ground-floor wall units to project from the bottom edges of the concrete shells. This thorough detailing required close coordination between the structural designers and the precast producer, SA Precast.

Preventing damage during transport through the desert

SA Precast is based in Adelaide in the southern part of Australia. The biggest challenge for the company was to ensure damage-free delivery of the precast elements to Perth through the Nullarbor Plains, a desert crossed by a dusty road filled with potholes. This is why the thickness of all precast elements was increased from the specified 70 mm to 135 mm, complemented by an additional 10 mm edge reinforcement. The two very slender, almost 10 m high spires were left...