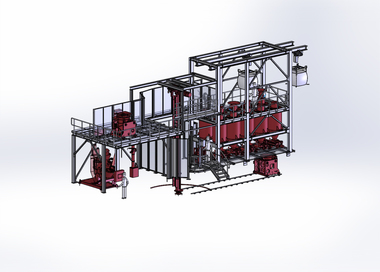

Flexible batch sizes, energy-saving drives, less soiling

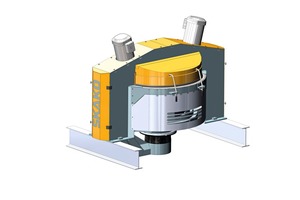

In 2013 leading concrete mixer manufacturers have presented new developments. Part I of the article takes a closer look at the first three of five systems, i.e. Haarup, Pemat and Eirich.

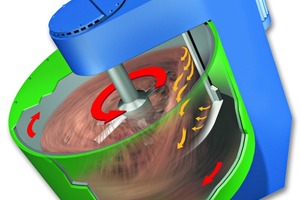

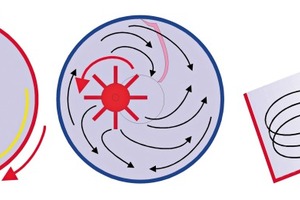

Renowned concrete mixer manufacturers have recently presented their new developments and launched innovative details to respond to market demand that mainly requires mixing systems to be appropriate for the increasing share of custom concretes whilst reducing energy consumption and soiling of mixing tools and components. Quite obviously, no ground-breaking developments were announced to achieve these goals, but a lot of effort went into the successful improvement of many details.

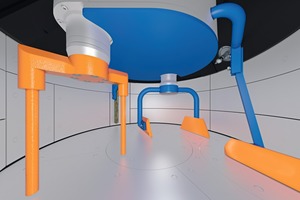

Significant reduction in material adhesions

Haarup Maskinfabrik A/S based in Silkeborg, Denmark, has launched a new...