Digital mold management system creates transparency in the concrete block plant

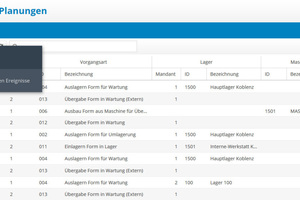

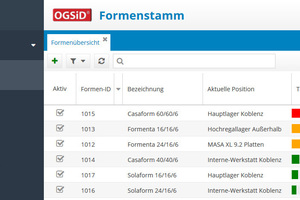

OGS develops, in collaboration with industry partners, a software for the management of concrete block molds. At any time, the users know the position of a mold, whether it has to be maintained and which mold is available in the plant as an alternative. The vision of future versions even goes far beyond this.

It is right in the middle of the season, the production is running at full capacity. Precisely then the machine operator reports that a concrete block mold is damaged and has to be replaced immediately. Fortunately, the company has a second mold for the production of the specific concrete block item. But, in which of the three branches is the mold and where there exactly? Nobody is able to give an answer offhand.

The scenario described, certainly, is the worst case – entailing the risk of production shutdown and financial losses. Nevertheless, the scenario is not made up out of thin air. In...