Digital evolution – From fiber to textile fabric

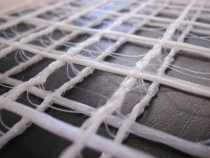

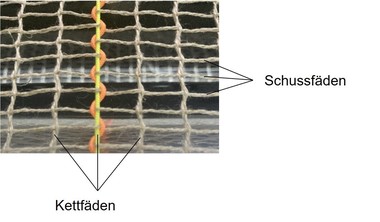

Carbon-reinforced concrete on the basis of textile reinforcement is a future-oriented alternative to reinforced concrete. When a patent application was filed for reinforced concrete in 1867, textile technology, especially the warp-knitting technology, had already been 100 years old. The origin of the warp-knitting technology dates back to the year of 1768. For some years now, the warp-knitting technology, being standard in the manufacture of textile fabrics, has also been used for manufacturing of fabrics with carbon fibers, which are used for carbon-reinforced concrete, for example.

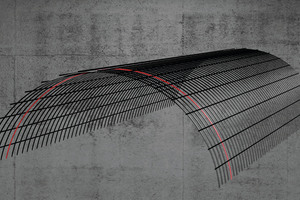

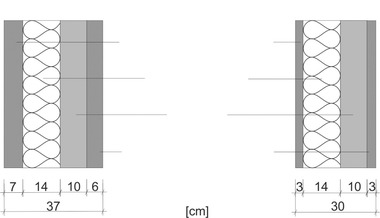

“Carbon reinforcements”, like steel reinforcements, are inserted into concrete – or into alternative matrices – particularly for the absorption of tensile forces. The carbon fiber is the basis of the carbon reinforcement. This fiber is made from polyacrylonitrile in a multi-stage combustion process. Alternatively, research is also carried out here on sustainable and resource-conserving technologies. A further development is wrapping by means of other fiber technologies.

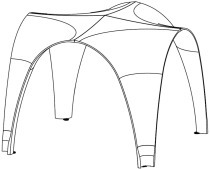

Fiber technology, machine technology, and textile technology have further evolved to a very high level in the past approximately 250 years. Today, textile fabrics are developed with CAD support and three-dimensional simulations. In 2005, a German global player had already made history in this regard on an international level, hence six years before the term of digitalization was used in Germany for the first time. The CAD data from the research department were used as a central data set both for the machine control system and as data set for the ERP system. Since that time, the entire information required for order controlling is provided by these data, which also represent the cost calculation. The future will reveal how the construction industry and the textile industry will develop a common language on the digital level.