Concrete as a climate killer? – Current findings in research and development tell a different story

The Association of Concrete Pipes and Reinforced Concrete Pipes (Fachvereinigung Betonrohre und Stahlbetonrohre e.V.; FBS) represents a total of 19 manufacturers of concrete duct systems in Germany. In addition to its original function, which is to define, certify and permanently ensure a higher product quality than that specified in normative requirements in the field of pipes and shafts, the Association has for some time been confronting the goals of climate protection.

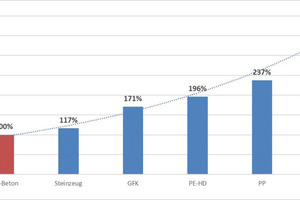

A scientific approach was chosen to meet the requirements of objectivity, transparency and robustness of the findings. Extensive environmental effects involved in the manufacture of concrete and reinforced concrete pipes were therefore initially collected by the Fraunhofer Institute and compiled in an environmental product declaration, a so-called EPD. In the next step, the findings were analyzed and, in the context of a life cycle assessment with other materials, interpreted in terms of their environmental effects. In the process, meaningful and valid environmental product data for alternative pipe materials (stoneware, GRP, HDPE, PP and PVC) were taken into account using the “Ökobaudat” data base provided by the German Federal Ministry of the Interior, Building and Community (Bundesministerium des Innern, für Bau und Heimat).

The findings show that, in direct comparison with the pipe materials mentioned above and across all nominal diameters, the use of FBS concrete pipes entails both the lowest CO2 emissions and the lowest environmental burdens during recycling.

Concrete producer Bieren, a long-standing and innovative member

of the Association of Concrete Pipes and Reinforced Concrete Pipes, has also recognized the importance of climate protection and the responsibility for future generations and is engaged in in-depth research and development to reduce CO2 emissions. The test results provide impressive evidence that by using optimized components and modified mixing ratios, CO2 emissions can be further reduced by up to 60 % compared to the average values (FBS concrete) without sacrificing quality properties – on the contrary: the findings indicate that the properties of high-performance concretes have significantly improved once again in comparison with standard concretes, thus reducing CO2 emissions by 50 %.

In short, it is evident that, in the discussion about meeting climate goals, concrete as a pipe material can make an important environmental contribution in particular in comparison with plastic

materials. In addition, there is further potential for innovation which concrete producer Bieren and the entire industry should make use of to advocate the material.