“CleanWater” project: Safe wastewater treatment in emerging countries

Within the „CleanWater“ Indo-German project, researchers are developing together with industrial partners a modular, resource-efficient solution concept for enabling wastewater treatment in rural regions. The complete article (in German language only) can be read in the „BetonBauteile Jahrbuch 2022“ yearbook, which is available at the Profil bookstore of Bauverlag.

Within the „CleanWater“ Indo-German project, researchers of the Institute of Textile Technology (ITA) at RWTH Aachen University (Aachen), the Department of Civil Engineering of the Indian Institute of Technology Madras (IIT-M) (Chennai) and the CSIR-Structural Engineering Research Centre (CSI-SERC) (Chennai) – in cooperation with the industrial partners Betonwerk Hentschel GmbH (Elsterwerda) and Raina Industries Private Limited (Mumbai) – are developing a modular, resource-efficient solution concept for enabling the treatment of wastewater in rural regions.

The Sustainable Development Goal 6 on „Clean Water and Sanitation“ of the United Nations defines the safe supply of clean (drinking) water as a social commodity of outstanding importance for the society. According to the description of the United Nations World Water Development Report 2020 [1], non-treatment of wastewater has serious consequences for the environment and the population.

Apart from the direct impairment of human health, the absence of wastewater treatment leads to the contamination of natural water resources, thus also having an impact on agriculture and the food industry. The proportion of untreated wastewater accounts for 80 to 90 % [1] in developing countries. This reveals a great imbalance of the possibilities of wastewater purification and the access to clean water prevailing between urban and rural communities. So as not to lose sight of difficult-to-reach regions outside the metropolitan areas, wastewater treatment plants have to be adapted to the existing requirements.

Lightweight designs as trailblazer

The application of lightweight construction technologies – such as fiber composites – has created a substantial technological progress in many industries (automotive engineering, aviation industry and the like). In the construction industry, textile-reinforced concrete (TRC) opens up new opportunities of lightweight construction and the conserving of resources.

The non-corrosive reinforcing materials enable a considerable reduction of the required concrete cover and the weight of the individual structural members. Their use in wastewater treatment plants allows, moreover, expanding maintenance and substitution intervals because of the high resistance of the materials.

Project context: international and interdisciplinary

Problems relevant to society are characterized by a high degree of requirements in a huge number of areas. The development of a solution for modular small wastewater treatment plants for rural areas used on a large scale requires the consideration of the composite material and its components, the adaptation of the structural design to the requirements of material, process and load along with an economic consideration of the production, distribution and sales.

In order to take all aspects of the problem into consideration in equal measures, an international and interdisciplinary research team was built up in the context of the „Clean Water“ project of the Indo-German Science & Technology Centre (IGSTC). On the Indian side, the project is coordinated by professor Ravindra Gettu of the IIT-M. Together with his colleagues, Prof. Gettu is developing an application- and material-specific design of the small wastewater treatment plants and an appropriate concrete matrix. The development of the structural design is supported by researchers of the CSIR-SERC, headed by Dr. Smitha Gopinath, using numerical simulation and structural testing. The development of the textile reinforcement for the structural concrete elements is carried out under the leadership of Professor Thomas Gries at ITA. Oliver Hentzschel (Betonwerk Hentzschel GmbH) and Dr. Mohit Raina (Raina Industries) establish the essential connection between research and the widespread use of the solution concepts developed. The production, sales and distribution as well as the operation of the small wastewater treatment plants are prepared in close collaboration with the scientific research progress. The aim is the installation of a complete plant in the region of Jhansi, India, at the end of the project. For this reason, the communities as well as non-governmental organizations are involved in the project already at the beginning of the project.

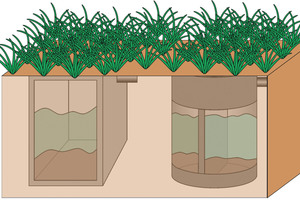

Concept of the small wastewater treatment plants made of TRC

Centralized wastewater treatment plants are regarded as ideal solution [2] for huge metropolitan areas. These wastewater management systems are connected to large infrastructure consisting of water supply networks and energy networks which are rarely available in rural areas or are very cost-intensive in their new implementation. This supply system alone accounts for up to 90 % of the implementation costs. Moreover, even in case of continuous maintenance, a complete replacement of parts or the entire plant is necessary after 50 to 60 years.

Decentralization can be realized with small plants which are allocated to individual apartment blocks or individual households [3]. Such decentralized plants are in particular suitable for suburban and rural communities. The expenditure for the realization of the tributary system is substantially lower owing to the proximity to the origin of the wastewater. They are ideal in order to reduce the pollution of water sources and to enable a direct reuse of water. In addition, their maintenance and operation is comparatively simple owing to the compact and robust technology [3].

Design development

The above-mentioned need for a decentralized wastewater treatment for the use in remote and rural regions as well as the potential of textile-reinforced concrete encourage contemplations regarding the implementation of small modular lightweight construction systems. In the long run, these systems shall be transported to the communities and implemented on site. The use of the lightweight material TRC significantly facilitates the transport and implementation without heavy-duty equipment.

Due to the clustering of households in the target region of Jhansi, the required size of tanks is determined to about 2.5 m³. In order to facilitate the production, it is intended that the individual sewage chambers are accommodated in individual tanks, as far as possible. In addition, the often missing electrical infrastructure is taken into account in the design development of the overall system. Local downslope will be utilized to ensure the functionality of the plant. In the numerical structural analysis at the CSIR-SERC five load cases were defined for different stages of implementation and operation. The underground installation in an empty operating state under a traffic load was identified as the essential critical load case here.

An underground installation is imperative because of the ground and weather conditions in the targeted region and a potentially required use of the surficial area.

Materials development

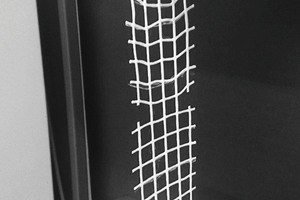

The components of the composite material evolve on the basis of the structural, mechanical and ecological requirements. A textile reinforcement made of alkali-resistant AR glass rovings of yarn count 2400tex is being developed at ITA. The reinforcement is manufactured in the form of a biaxial warp-knit fabric in a tricot in counternotation so as to create a grid-like, open structure. In this regard, different grid openings are considered which have a severe influence on the load-bearing reinforcement cross-section per meter, the required number of layers and thus the manufacturing conditions. The reinforcement structure which is currently under research requires one to four layers of reinforcement for grid openings of 8 to 25 mm and depending on the coating material used. The IITA-Madras is carrying out the development of a concrete matrix.

In this regard, they must find a compromise between a fine-aggregate concrete matrix allowing a small textile grid opening, and the costs incurred. Furthermore, the material must also feature a high strength in contact with wastewater and, at the same time, it must be composed of material available in India for cost reasons. At this particular time, specimens of the above-described reinforcement and the matrix made of cement, fly ash, silica fume, quartz sand and quartz dust are subject to long-term tests for evaluating the durability.

Acknowledgement

The author and the entire research team of the „CleanWater“ project thank the BMBF (Federal Ministry of Education and Research), Germany, the DLR Projektträger, Germany, and the DST (Department of Science and Technology, Government of India) for funding and the coordination of the „CleanWater“ research project within the Indo-German Science & Technology Centre (IGSTC). The mechanical tests at IIT Madras were conducted at the Laboratory for Mechanical Performances of Civil Engineering Materials, partly funded by the FIST Grant SR/FST/ETII-054/2012.

REFERENCES/LITERATURE