Carbon-fiber reinforcement combined with the orientation effect of 3D pressure

Attempts have long been made to replace conventional steel reinforcement with suitable alternative materials. In this context, cost-effectiveness has been given special priority. At Augsburg University, in Germany, an innovative cement-bound composite material with oriented short carbon fibers was developed as part of current basic research of materials science. The results show definite advantages over reinforced concrete with regard to durability and loadbearing capacity.

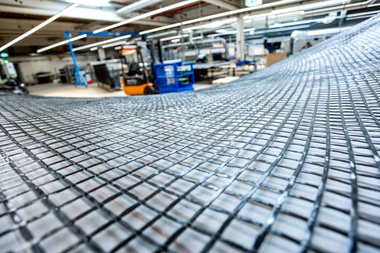

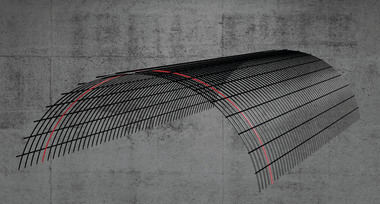

In the new material, short carbon fibers oxidized by thermal treatment are used; by a nozzle-supported process, the fibers are oriented in the direction of stress. The fibers are heated to a specific temperature in a muffle furnace, which removes the fiber surface coating applied in the factory, while enriching the surface with oxygen. This results in a notably enhanced bond between fiber and cement matrix. The fibers become hydrophilic, with the result that fewer fiber agglomerations are created. That is of special importance since the concrete must be extruded through a nozzle only a few millimeters wide in order to produce fiber orientation. By this extrusion process, approximately twice as many fibers can be oriented in the desired direction in the plane than is the case with sample cast specimens.

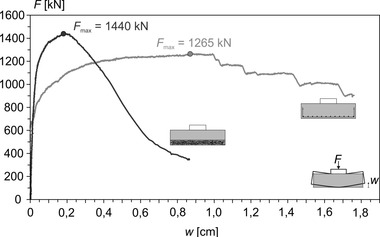

The short carbon fibers have the effect that additional cracks occur in the cross-section after the initial crack, thus creating many micro-cracks instead of one single macro-crack. With progressive deformation, this results in greater loadbearing capacity, which is referred to as deformation or deflection hardening. The increase in flexural tensile strength in the post-cracking area can, with 3.0 vol.-% of carbon fibers, be accordingly increased more than 13-fold: i.e., to 120 MPa [1] in comparison to unreinforced specimens. It is noteworthy here that compression and flexural tensile strength are equal. In this way, very high tensile stress can be absorbed – without any reinforcing steel whatsoever. Additional advantages of the new composite materials are their great resistance to corrosion and the usability of recycled carbon fibers.