Additive manufacturing – Paradigm shift in the construction industry

The reduction of CO2 emissions, the decrease in resource consumption

and the transfer of our linear material flows into circular economies are the global challenges of our time. The construction industry plays an important role in this regard: Firstly, the demand for new buildings

and infrastructure facilities will increase in the next decades

because of the growing population. Secondly, the construction of buildings is characterized by a high degree of individualization owing to local site conditions.

Industrial series production and CNC-based individualized production did not become accepted because they do not allow the individualization required and are inefficient. However, the technology

of additive manufacturing is fundamentally different and allows for a paradigm shift in the construction industry, in particular, in concrete

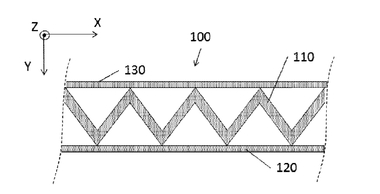

construction. The major advantage of 3D concrete printing is the fact that automation and individualization are not contradictory. In a 3D concrete printing process, material is only built up where it is required for structural and functional purposes. In this way, a drastic reduction of the material input is possible. Therefore, 3D concrete printing is eco-friendly and cost-effective.

However, the introduction of additive manufacturing techniques in the construction industry not only requires technological developments. It also requires a design language corresponding to the technology. In this regard, we are just at the beginning of a new era. The Transregio

TRR 277 project is aiming at increasing resource efficiency and productivity in the construction industry and paving the way for a new design in architecture and engineering. For this purpose, research teams are searching for a new logic of shape, being based on structural design principles and, in particular, on an efficient control of the force flow. However, the integration of additional functions (e.g., building physics) also controls the structural design.

The challenges here are the reinforcement strategies and new composite materials, for instance, but also the digital connection of additive manufacturing technologies into the preliminary planning process

and the integration in automated construction processes.