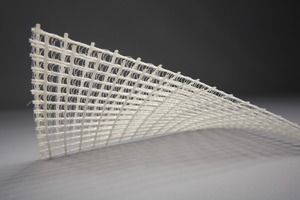

3D textile-reinforced concrete façade elements of only 3-cm thickness

V. Fraas Solutions in Textile has developed an innovation for textile reinforcement in concrete façade panels and integrated it in architectural concrete façades from Hering Bau. These betoShell®BIG 3D textile-reinforced façade panels from Hering Bau, with integrated SITgrid® from V. Fraas, are used for the first time for the new construction of Dresden Technical University. Here, 530 façade elements measuring up to 1.30 x 2.00 m and of only 3-cm thickness were installed. The façade designed in this manner covers a surface area of 1,070 square meters.

The exterior face of the new building of the Institute’s Department of Civil Engineering at Dresden Technical University was to mirror the utilization of the building. Since the building will be occupied by the Institute for Construction Materials Science, an especially innovative material was to be chosen for the design of the façade. Accordingly, the Dresden architects Schubert Horst designed a white-colored, 3D textile-reinforced curtain façade with acid-treated surface of betoShell-BIG elements with integrated SITgrid, making the building in this way a pilot project for this innovative architectural concrete. betoShell-BIG with integrated SITgrid has been approved by the German approval body for construction products and types of construction, Deutsches Institut für Bautechnik.

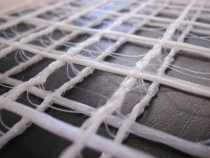

What makes the new façade system so special, is the reinforcement in the form of a 3D textile. It consists of two textile layers spaced 10 mm apart, connected pressure-stiff to each other by so-called pole threads. 3D textiles, in bond with such materials as, e.g., concrete or plastics, are characterized by an enormous loadbearing capacity at an extremely low own weight. V. Fraas Solutions in Textile has succeeded in developing a production line on which this 3D textile reinforcement can be manufactured for the first time in large sizes. It is therefore now possible to manufacture slender and lightweight concrete façade panels of larger sizes of up to 1.20 x 2.40 m. In comparison: a façade panel of similar size reinforced with steel, due to the corrosion protection needed, would have to have a thickness of at least 80 mm. The advantages of a thinner wall buildup are numerous and varied. First of all, a more effective insulation can be installed without adding too much to the thickness of the overall building shell. Secondly, the reduced thickness of all walls leaves more space for the interior rooms. The low weight of the thinner architectural concrete panels facilitates transport and installation. Lower loads on the façade, moreover, reduce the high structural requirements. Accordingly, textile-reinforced concrete façades are especially suitable for energetic façade restoration, as well as for new buildings.

More advantages result from ecological viewpoints: The thin-walled textile-reinforced betoShell elements, relative to a comparable steel-reinforced façade, reduce the resources needed for production by up to 80%. But not only raw materials are saved. The energy required for production, transport and removal is reduced, and less than CO2 emission is released. The same applies in comparison to other façade systems. Thinner and more slender architectural concrete elements allow more freedom in façade design. The wide range of possibilities for surface design with betoShell offer additional individual design options. Aside from the addition of pigments and natural and glass aggregates of different color and shape, betoShell façade surfaces can, among other things, be sandblasted, ground or acidified. Relief structures and individual design and photo concrete, Betoglass® or BlingCrete™ façades are also possible.

CONTACT

V. Fraas GmbH

Solutions in Textile

Orter Str. 6

95233 Helmbrechts/Germany +49 9252 7030

sit@fraas.com www.solutions-in-textile.com