Driven pile production on a circulation system

The Austrian company Nägelebau is located in Sulz-Röthis, Vorarlberg, near Lake Constance. In addition to a construction company they operate a precast concrete plant. The Nägelebau Company has also established a good reputation in the field of geothermal energy and earth building that has made them famous far beyond the borders of the lower Rhine Region.

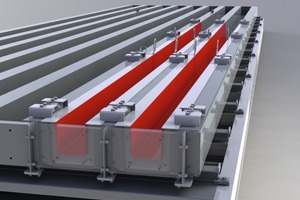

A new pallet circulation system went into operation in the precast concrete plant in 2010. The factory concept had to fulfill several tasks. First of all, they had to manage the limited space on the existing, non-expandable plant site. And the other point was to find optimal conditions for the vast production program. That they have managed to achieve this is not only confirmed by the company Nägelebau as the operator, but also the many visitors are impressed by the overall concept.

In addition to flat components, such as facades, wall panels, spandrel panels, parapet elements, etc., it was very important for the company Nägelebau to be able to produce different types of driven piles with this circulation system.

These piles are not just used for the usual foundation. The company Nägelebau together with its subsidiary Enercret has developed a system of how to use these pile foundations for energy production in the form of geothermal energy. The earth can be used as energy source in a number of ways. Generally known are the vertical soil sensors, the horizontally laid ground collectors, the trench collectors and the absorber systems that are embedded in the strip footings and floor slabs.

In the latter options, the availability of the soil as an energy source is quite limited, and with regard to the soil sensors, the additional cost of drilling and installation of the sensors is significantly. More than 20 years ago the company Nägele GmbH has embedded absorber systems in the reinforced concrete piles and diaphragm walls and has developed the technology for today‘s production. Further information available at:www.enercret.com

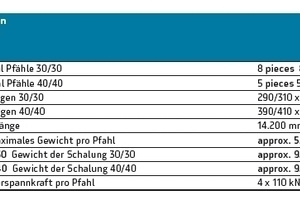

The main dimensions of the piles are 30 x 30 cm and 40 x 40 cm and they are offered non-prestressed and prestressed. The idea of placing rigidised formworks on the pallets, was quickly raised, but the project team consisting of experienced employees from Nägelebau and Weckenmann, realized that a conventional formwork would be far too heavy and thereby the payload would be too low.

The Weckenmann engineers made an alternative proposal, which allowed producing either, 8 pieces of 30 x 30 cm piles or 5 pieces of 40 x 40 cm piles with a max. length of 14.2 m and a single prestressed force of 4 x 110 kN in one formwork. The formwork weight was achieved by a light but extremely stiff steel plate construction, the construction was accompanied by extensive calculations.

With this manufacturing concept the following advantages have been achieved:

» Production of non-prestressed and prestressed piles with one formwork.

» Perfect surfaces and precise dimensions.

» Use of the circulation technology for efficient production of the piles at reduced costs.

» High early strength of concrete by heat treatment in the curing chamber.

Upon request for conical piles Weckenmann responded quickly and proposed a concept for complementary formworks, which are inserted in the existing formwork. The pile is made in there by tapering over a length of 8 m to about 100 mm. The realization of the fixation takes place using switchable magnets. This is why the installation and removal is very fast. The front mould of the piles is fixed magnetically.

The working process is divided into the following steps:

» Feeding of the tension wires and/or insertion of the reinforcement

» Placing of the front moulds

» Insertion of the conduits for geothermal energy utilization

» Concreting with the concrete distributor

» Compacting by means of horizontal shaking

» Screeding with the screed, which is attached to the concrete distributor

» Storing in the curing chamber at approx. 45 °C.

» Stripping with an overhead crane

» Manually cleaning of the formwork and application of the formwork oil.

Summary

With a cleverly planned pallet circulation system much more than flat concrete parts can be produced. Piles, small columns and beams as well as steps are feasible and increase the benefits of the technology used. The company Nägelebau has secured its position as a premium manufacturer of high quality and innovative precast concrete products with this investment. It will be interesting to see what the entrepreneurs from Vorarlberg will come up with next.

CONTACT

Nägelebau GmbH

Bundesstraße 20

6832 Röthis/Austria

+43 5522 41526 0

info@naegelebau.at

↗ www.naegelebau.at

WECKENMANN

Anlagentechnik GmbH+Co.KG

Birkenstraße 1

72358 Dormettingen/Germany

+49 7427 94930

info@weckenmann.de

↗ www.weckenmann.de