CONTROLS S.R.L. · Hall C1, booth 117

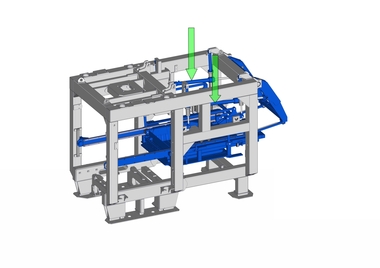

The continuous search for new technological solutions for testing equipment for the construction industry backed up with over 40 years of experience has led Controls to an important threshold which shows, yet again, how well directed research investment can result in technological successes both in terms of quality and price. The new range of Pilot 4 compression machines include ES Technology (Energy Saving) which allows accuracy thanks to automatic closed loop control, high productivity thanks to double stage pump and energy saving thanks to variable flow pump. A new control board reads and...