Technology and application

You know how it goes: a company has developed a new product. Its team put a lot of thought, sweat and many an evening in the workshop and office into the development. With pride, they praise the many advantageous technical characteristics of the product, and they enthuse over its perfect design. The potential buyer listens and nods his head. But he is really only interested in the one product characteristic: “And what is the cost advantage for me when I buy and install the new product?”

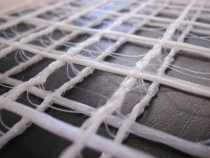

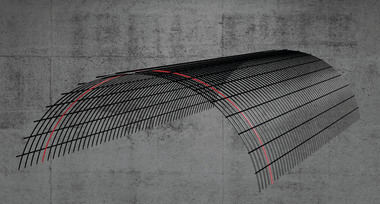

Something similar could be observed at this year’s Carbon and Textile Concrete Days in Dresden, Germany (read the detailed report in BFT International 12/2018): The lectures revolved around the latest research results on carbon and textile concrete reinforcement – physical, constructional and structural advantages were often in focus. The audience in the hall listened and asked few questions. During coffee breaks we learned more from the practitioners: “Non-corrosiveness, thermal insulation, higher loadbearing capacity – all of that is, to me, of secondary importance. In our products we replace parts of the steel reinforcement with textile reinforcement where it, in structural terms, makes no difference. We do that simply to save weight. We can transport more light construction elements on a truck and save considerable costs.”

This comparison of course falls short. Research and development work in the field of carbon and textile concrete, other than in the scene described above, is not complete and there are only few products that have been developed to market maturity. But the comparison helps us to understand how different the expectations placed on new technologies can be in their development stage. These differences will quickly disappear when more and more ready-to-use applications and products will soon come to the market.