Service life forecast for concrete

Overview

Concrete structures are exposed to complex actions with an influence on durability that may lead to substantial damage during their service life, which has been increasingly observed in transport infrastructure in the recent past. Service life forecasts provide the opportunity to estimate the expected progression of damage in concrete in order to initiate timely maintenance and repair measures. Service life forecasts essentially rely on damage models and probabilistic methods, such as specified in the fib Model Code for Service Life Design [1]. This paper outlines current practice with respect to service life forecasts and demonstrates more comprehensive methods to realistically assess the progression of damage in concrete. These methods also provide the opportunity to make building with concrete more cost-efficient and more sustainable.

Service life forecast for concrete structures – current situation

Preparing a service life forecast essentially requires mathematical models (material laws) with quantifiable action and resistance parameters, as well as definitions of unwanted structural or component-related conditions (limit states). By comparing action and resistance values this approach makes it possible to calculate the limit-state-related reliability at any point in time, which, in turn, is compared with a maximum permissible target reliability.

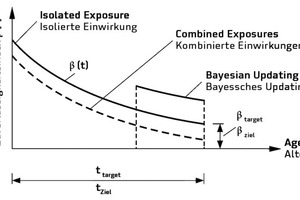

Such a forecast results in a graph that reflects the trend of the reliability index β(t) over time until the target reliability βtarget is reached, as well as the associated design service life ttarget (Fig. 1). The design service life of infrastructure usually amounts to 100 years. In the course of its use, the safety margin between exposure and resistance can be continuously measured, and the change in reliability at the time tup can be captured through Bayesian updating when applying the probabilistic service life forecast method (Fig. 1). Corresponding codes and standards for probabilistic service life forecasts have already been published [1, 2, 3].

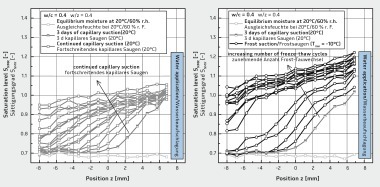

Currently, the forecast routine merely permits measurement of carbonation- and chloride-induced depassivation of the reinforcement in uncracked concrete. Influences of simultaneous mechanical actions are not considered. Furthermore, the models provided in current codes and standards only capture isolated exposures or damage mechanisms, which means that interactions are neglected. Moreover, no appropriate material models exist to reflect freeze-thaw impact.

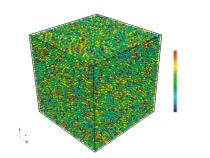

In reality, however, environmental exposures are correlated with mechanical loads acting on the structure, which is associated with a change in the specific damage mechanisms. Furthermore, cracked concrete structures can always be assumed for a building or structure under typical conditions of use. Also, durability-relevant exposures do not occur in an isolated manner. Rather, they act on the structure simultaneously, such as in the case of combined exposures to carbonation, freeze-thaw cycles, solar irradiation, and chlorides (from de-icing salts). These exposures thus influence each other both chemically and physically. Fig. 2 shows a schematic that reflects combined exposure of infrastructure to mechanical loads and environmental influences.

Combined exposures usually lead to an increase of concrete damage, and thus to reduced reliability (Fig. 1).

Service life forecast for concrete structures – outlook

As outlined above, complex environmental actions strongly limit the usability of engineering structures built from concrete. It is generally undisputed that these structures currently incur high maintenance costs, which will also be the case in the future. For this reason, it is a huge challenge, both from an academic and an economic point of view, to provide an accurate forecast of the service life of concrete structures with the aid of realistic damage modeling and probabilistic methods. Related opportunities lie in the development of appropriate “tools” to optimize maintenance scheduling for major concrete structures. As a result, building with concrete will become more cost-efficient and more sustainable.

In the future, currently available damage models of carbonation- and chloride-induced reinforcement corrosion must be improved to more accurately describe the damage pattern. More specifically, appropriate material models need to be provided to capture freeze-thaw damage in concrete in a realistic manner. Moreover, available damage models must be adjusted to include cracked concrete structures. Finally, it is indispensable to realistically model combined, interacting exposures of infrastructure applying the principles of system reliability theory. In addition, the use of other analytical methods such as Markov chains or artificial neural networks should be reconsidered. A related modification of current codes [1, 2] should be envisaged.