RemoTension

Prestressed concrete is distinguished from common reinforced concrete by systematic pretensioning of the steel reinforcement. This allows for concrete structures with higher load-bearing capacity and larger spans in comparison to normal, non-tensioned reinforcement steel. Prestressed concrete is used, for example, in bridge construction, in container construction, in building construction for hollow core slabs or precast prestressed floor units. The correct pre-tensioning is relevant to safety and absolutely necessary for achieving the load capacity of the respective concrete element as planned.

So far, the risk of error in the tensioning process could only be minimized by the attention of the workers operating the tensioning equipment. Tensioning reports required for quality assurance could only be generated by the operating staff manually, once again including the respective potential for error and manipulation. As a consequence, all tensioning equipment available on the market so far protected the high safety risk for the final product only insufficiently.

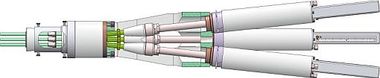

In order to minimize the safety risk in respect of tensioning, the Weiler company is launching the RemoTension single wire stressing jack. The system allows for a digital tensioning process that is parameter controlled, automatic measurement of pressures and the length of tension as well as the automatic calculation of the tensile force applied – as a result, the specified stressing forces can no longer be exceeded nor undercut; an automatic generation of a digital, unchangeable record of tensioning and a digital, unchangeable tension assessment – tensioning record and assessment can be exported to the master control system via WLAN, USB or mobile service; it is possible to import the cross-section graphic from the architectural or structural design directly, as well as the specification of the stressing force including tolerances for the single wires/strands by the administrator; the technical precautions to prevent the use of wrong stressing jacks – graphic specification for the operator “stress wire X by using stressing jack of type Y”. When the operator initiates the machine, the tensioning process begins and only after the complete execution of the same according to the specified parameters, the specification for tensioning the next wire/next strands is provided.