More than 13 million tons of color pigments from Krefeld for 90 years

The specialty chemicals company Lanxess is producing iron oxide and chrome oxide pigments for numerous applications in the world’s largest production plant for inorganic color pigments in Krefeld-Uerdingen – and has been doing so for 90 years now. Whether used in the paint coat on the Eiffel Tower in Paris, the red asphalt in front of Buckingham Palace in London or numerous products we encounter in our day-to-day lives – pigments from Lanxess are used all around the world. What started on a small scale 90 years ago has turned into a genuine success story: Since the launch in 1926, more than 13 million metric tons of pigments have left the plant in Krefeld-Uerdingen.

The IPG business unit is part of the Performance Chemicals segment of Lanxess, which recorded sales of Euro 2.1 billion in fiscal year 2015. Further sites are located in Porto Feliz (Brazil), Starpointe Burgettstown (United States), Branston, (United Kingdom), Vilassar de Mar (Spain), Sydney (Australia), and Shanghai and Ningbo (China). IPG has a global workforce of approximately 2,000 people, around 800 of whom are working in Krefeld-Uerdingen.

On September 21, Jörg Hellwig, head of the Lanxess Inorganic Pigments business unit (IPG), provided the many anniversary guests on the occasion of a celebration with information on the past and future developments of the company. Together with Krefeld’s Mayor Frank Meyer and Deputy Mayor Gregor Micus, he launched the new “Besser Lernen” (Learn better) initiative with the symbolic push of a button. The initiative will award projects run by educational institutions and youth organizations in Krefeld with a total amount of Euro 50,000.

Immediately thereafter, the visitors could get an idea of the production process and the use of pigments for colored construction materials during a guided tour through the application laboratory of construction materials and the iron oxide production plant.

Geared towards customers and competitiveness

IPG supplies some 5,000 users worldwide with pigments that are used to color a wide variety of products. “Even from our customers‘ point of view, our decades of experience in manufacturing quality products and in process development and optimization sets us apart from many of our competitors,” Hellwig stated. At its most important site in Krefeld-Uerdingen, the business unit harnesses the entire value-added chain for iron oxide production – from synthesis through to packaging. “One very special advantage of the site is its high degree of plant automation, which enables maximum production output and thus excellent cost efficiency. What is more, here in Krefeld, we have extremely well-trained staff and very high and sustainable standards as regards both environmental considerations and production, giving us a key edge over the competition internationally, too,” Hellwig said. “The most important thing, however, is that we have a team that is extremely good at what it does, is full of ideas and is highly motivated – without that we would never have been able to achieve the success that we now want to carry forward.”

At the Krefeld-Uerdingen site alone, Lanxess produces more than 280,000 metric tons of color pigments per year, with the global figure at 375,000 metric tons – and growing. Lanxess is committed to what is its second-largest production site worldwide. Between 2005 and 2015, the specialty chemicals company invested some Euro 420 million in this facility, approximately Euro 200 million of which benefited the pigment production alone. “Besides the quality and performance of our products, the innovative capabilities and creativity of our employees have played an important part in helping our pigments under the now world-famous Bayferrox brand to carve out a leading position on the market over the past nine decades,” Hellwig emphasized.

Fast-paced company history

In 1925 Julius Laux, head of the aniline plant in Uerdingen, discovered that the presence of salt solutions led to the formation of oxides with increased color strength that were ideal for use as pigments.

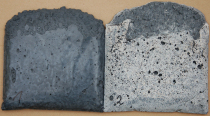

Just a short time later, synthetic iron oxides had established a firm place on the market and were being used primarily to color linoleum, surface coatings and construction materials. In the 1960 s, annual production volumes climbed to more than 100,000 metric tons. The product range has also grown considerably over the decades. While customers could choose from 25 colors in 1931, the current range extends to more than 100 colors.

In 1976, the iron oxides from Uerdingen got their own special name and, since then, Bayferrox has been the most important global umbrella brand for these pigments.

A key product development came in the 1990 s with the introduction of microgranules, which support low-dust handling and are free flowing for metering purposes. The latest groundbreaking innovation is the new plant in Ningbo, China. IPG developed a completely new technology.